Configuration and programming in STEP 7

8.3 Programming SIDOOR instructions

ATD4xxW Door Controller for Industrial Applications

256

System Manual, 01/2017, A5E38080677-AB

8.3

Programming SIDOOR instructions

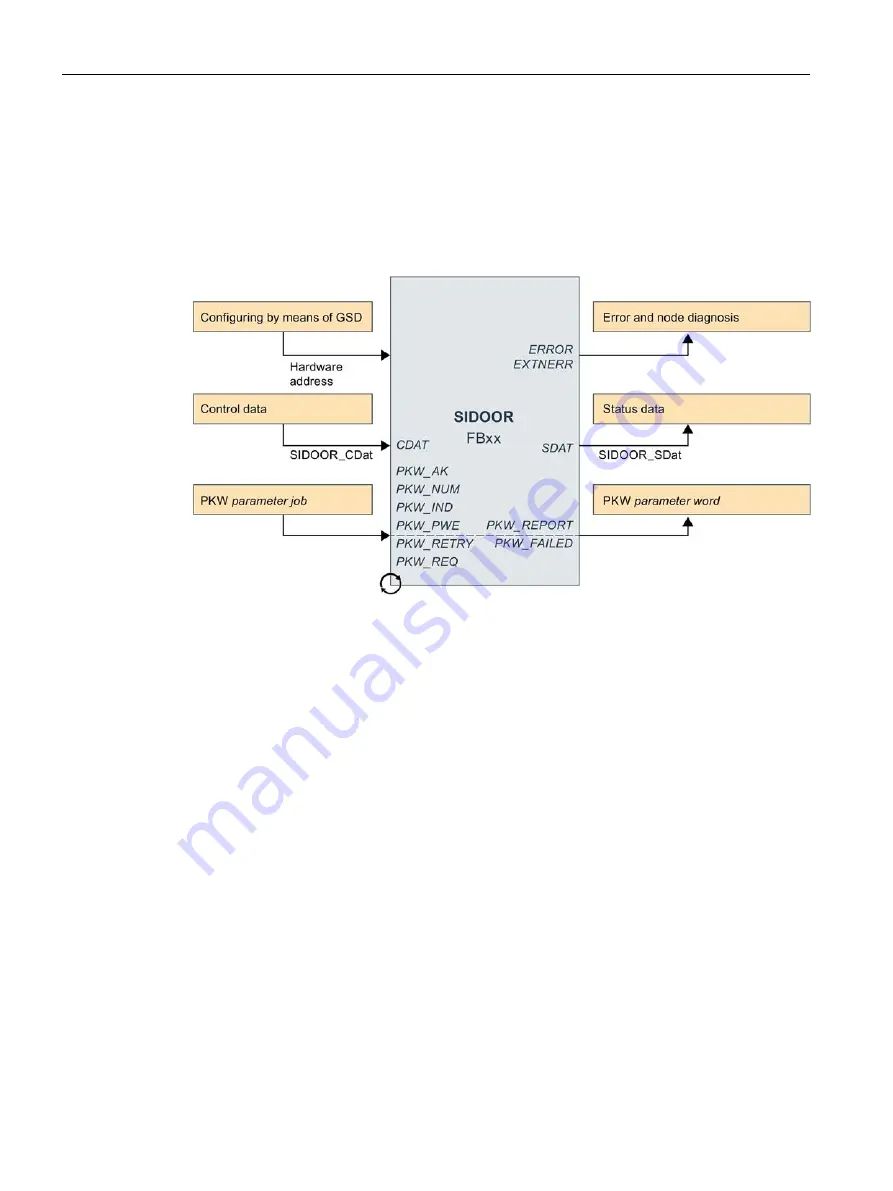

PROFINET or PROFIBUS SIDOOR controllers are configured via certified GSD files. This

ensures compatibility with different industrial automation systems. A function block is

provided for fast and simple interfacing of a SIDOOR drive to a SIMATIC. This function block

was implemented for PROFIBUS or PROFINET communication and for various SIMATIC

families. The blocks always operate in accordance with the principle described below.

Figure 8-1

SIDOOR function block

The SIDOOR function block handles the data processing of exactly one SIDOOR controller.

Therefore the block has to be called with a data instance for each SIDOOR bus node. There

are no restrictions on the call cycle of the SIDOOR function block. A cycle time of >10 ms is

recommended to make optimal use of the resources.

The selected SIDOOR bus node is localized by specifying a hardware address ID. Every

time the function block is called, the control data is transferred to the controller according to

the "SIDOOR_CDat" structure. Additionally, the current status data is updated in accordance

with the "SIDOOR_SDat" structure. The availability of the SIDOOR bus node is also

checked, and the node diagnostics data is updated. A parameter job is acyclic, and is

processed during the course of several call cycles of the SIDOOR function block. The block

returns the result and the status of the parameter job. The block number can be changed.

Response to errors

If communica

tion and/or the block is interrupted (ERROR ≠ 0000

hex

), the response is as

follows:

●

No parameter job is accepted.

●

The states of the output parameters PKW_REPORT and PKW_FAILED remain

unchanged.

●

All control data (CDAT) is rejected.

●

All elements of the SDAT status data structure are set to 0.

Summary of Contents for SIDOOR ATD401W

Page 1: ......