Cleaning / Maintenance / Frost Protection

Before you begin any maintenance work,

unplug the machine or switch off the fuse.

Turn the tap off.

Cleaning your machine

!

Never use solvents, as these can damage

machine components, and produce toxic

vapours. Explosion hazard!

!

Never spray the machine with water.

Casing and control panel should only be clea-

ned with a standard, solvent-free, non-scouring

cleaning agent.

Cleaning the detergent drawer

1. Pull out the drawer out completely.

2. Press the cover of the siphon tube inside the

bucket of softeners, pull out the whole drawer.

3. Turn the siphon tube cover upward.(see figure

12

).

4. Clean the drawer and the siphon tube with tap

water.

5. Replace the cover of the siphon tube.

6. Insert the drawer.

Descaling is not usually necessary if you use the

right amount of detergent,

!

Descaling agents contain acids which can

corrode machine components and cause

discoloration of laundry.

However, if you do want to descale your

washing machine, follow the manufacturers

Instructions.

Cleaning the drum

Any rust, caused by metal objects left in the

machine, must be removed using a chlorine-free

cleaning agent (check the description of

contents on the pack). Never use steel wool.

Water inlet hose

To avoid water damage, arrange for the hose to

be checked by a specialist every 5 years.

Cleaning the pump

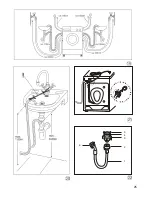

Fig.

15

,

16

,

17

The pump must be cleaned:

if the pump has been blocked by some

foreign object, such as a button or paper

clip,and water cannot be pumped out.

after washing very fluffy items.

Before cleaning the pump, water must be drai-

ned out of the machine. If the pump has been

blocked, up to 20 litres of water can run out -

so keep a bucket handy.

Cleaning procedure:

1. Remove the base cover from the front of

the machine.

!

Scalding hazard. Allow hot water to cool

down.

2. Carefully unscrew the pump cover- do not

remove it completely- and let the water

drain out into a shallow container (let the

remainder drip onto a floor cloth). Repeat

the operation until there is no water left

in the machine.

3. Remove the pump cover.

4. Remove any foreign objects and fibrous

deposits. Clean the inside of the pump.

Ensure that the vanes on the pump move

freely.

5. Screw the pump cover back on.

6. Replace and close the base cover.

7. Pour approx. 2 litres of water into the

detergent drawer and start the Drain

programme. This prevents detergents from

passing unused straight into the drains the

next time the washing machine is used.

Descaling the machine

en

16

Summary of Contents for Silver WD 1000

Page 25: ...18 18 5 4 7 6 8 23 ...

Page 26: ...10 11 12 13 14 15 16 17 9 18 24 ...

Page 27: ...20 19 25 21 22 5 4 3 2 1 6 ...