4-20

CM35 Counter Module

(4) J31069-D0416-U001-A5-7618

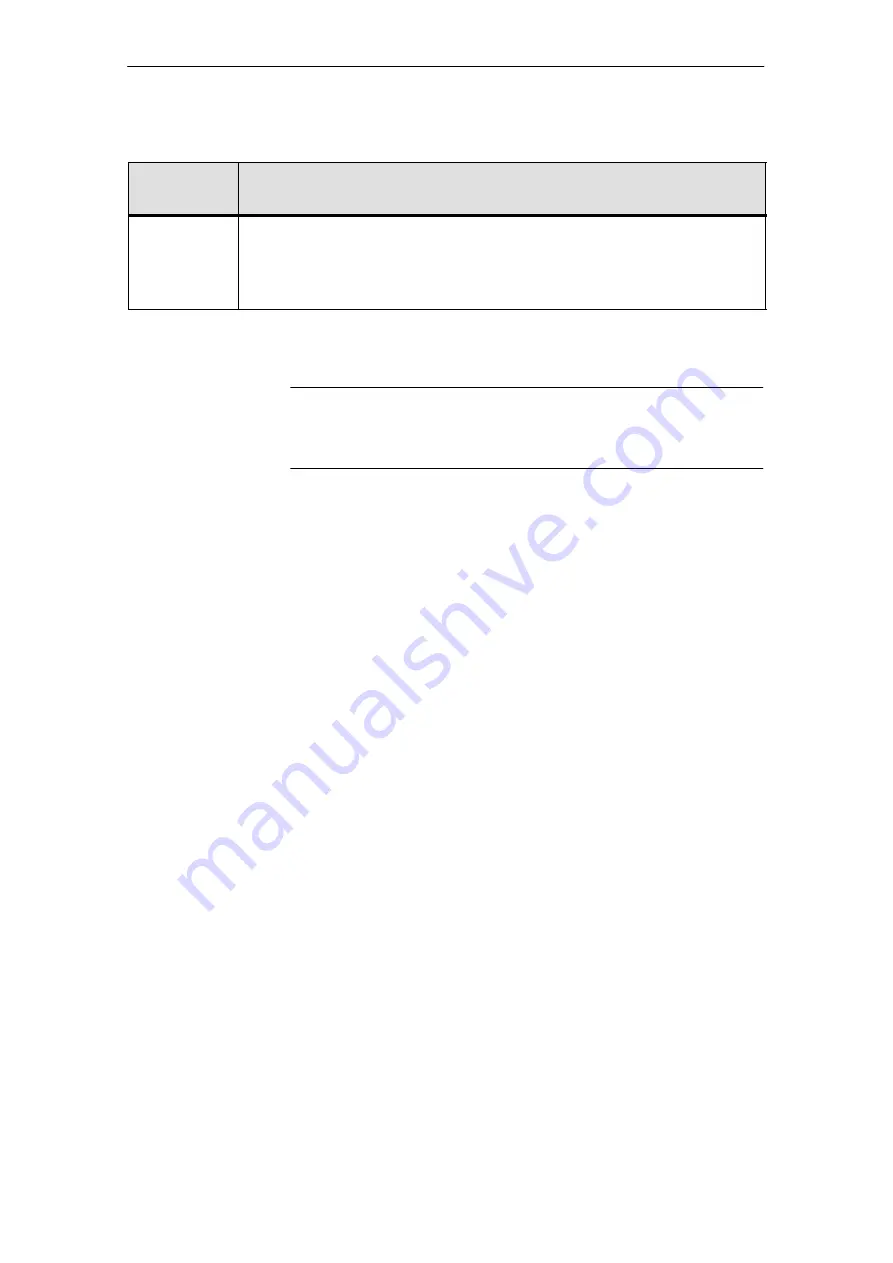

Table 4-11

Allocation of the I/O address area for writing via direct I/O accesses

Output Area (16 Bytes)

Offset to

Module Address

(by Word)

+4 to +14

(With SFC55:

2 to 12)

Parameterization data

Pulse counter:

Parameter blocks 1 to 3

Period duration measurement: Parameter block 1

Timer:

Parameter blocks 1 to 3

Positioning:

Parameter block 1 (subnumbers 0 to 4)

Parameter block 2 (subnumbers 1 to 4)

Note:

With parameterization via SFC55, the data to be transferred are set up the same as

output words 2 to 14.

Note

Only word or double--word accesses to even addresses can be used for I/O

accesses.

Data Communication with the CM35

Summary of Contents for SIMATIC CM35

Page 1: ...SIMATIC Counter Module CM35 Manual Release 06 2000 ...

Page 9: ...vi CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Table of Contents ...

Page 10: ...1 1 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Product Overview 1 ...

Page 20: ...2 1 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Function Description 2 ...

Page 23: ...2 4 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Function Description ...

Page 47: ...3 24 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Commissioning ...

Page 48: ...4 1 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Data Communication with the CM35 4 ...

Page 70: ...5 1 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Pulse Counter Operating Mode 5 ...

Page 98: ...7 1 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Timer Operating Mode 7 ...

Page 112: ...8 1 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Positioning Operating mode 8 ...

Page 131: ...8 20 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Positioning Operating mode ...

Page 133: ...A 2 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Literature ...

Page 134: ...B 1 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 EC Declaration of Conformity B ...

Page 135: ...B 2 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 EC Declaration of Conformity ...

Page 141: ...Glossary 6 CM35 Counter Module 4 J31069 D0416 U001 A5 7618 Glossary ...