Installing the Device

2.4 Connecting the Failsafe Alarm Relay (If Equipped)

Removing the Device

To remove the device from a DIN rail, do the following:

1. Insert a flathead screwdriver into the slot of the sliding release and move it

down.

1

DIN Rail

2

DIN Rail Adapter

Figure 2.2

Removing the Device from a DIN Rail

2. Swing the bottom of the device away from the DIN rail.

3. Lift the device off the DIN rail.

2.4

Connecting the Failsafe Alarm Relay (If Equipped)

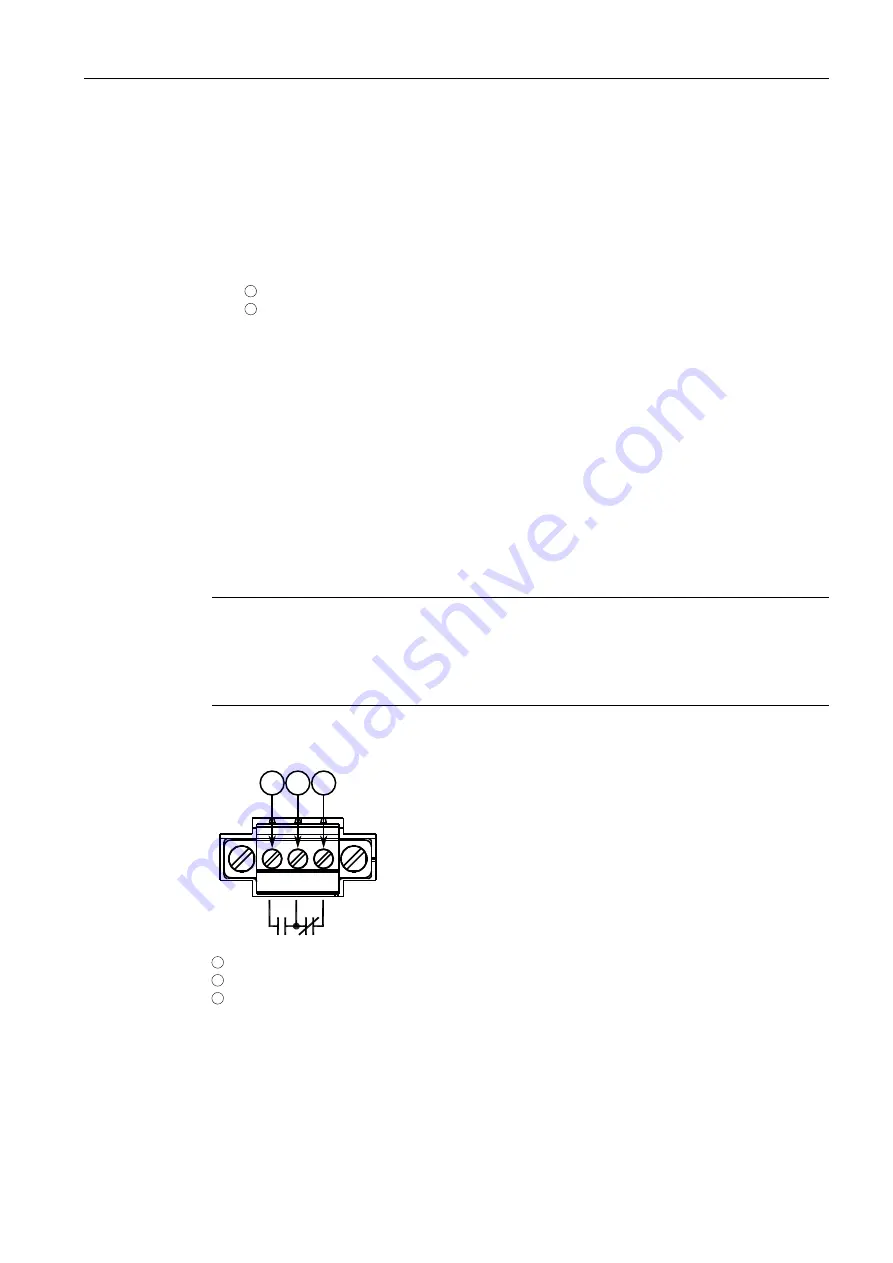

The failsafe relay can be configured to latch based on alarm conditions. The NO

(Normally Open) contact is closed when the unit is powered and there are no active

alarms. If the device is not powered or if an active alarm is configured, the relay

opens the NO contact and closes the NC (Normally Closed) contact.

Note

Control of the failsafe relay output is configurable through RUGGEDCOM i801 . One

common application for this relay is to signal an alarm if a power failure occurs.

For more information, refer to the

RUGGEDCOM ROS Configuration Manual

for the

RUGGEDCOM i801.

The following shows the proper relay connections.

1

3

2

1

Normally Open

2

Common

3

Normally Closed

Figure 2.3

Failsafe Alarm Relay Wiring

8

RUGGEDCOM i801

Installation Manual, 01/2021, C79000-G8976-1003-06