9-35

ET 200U Distributed I/O Station

EWA 4NEB 812 6087–02b

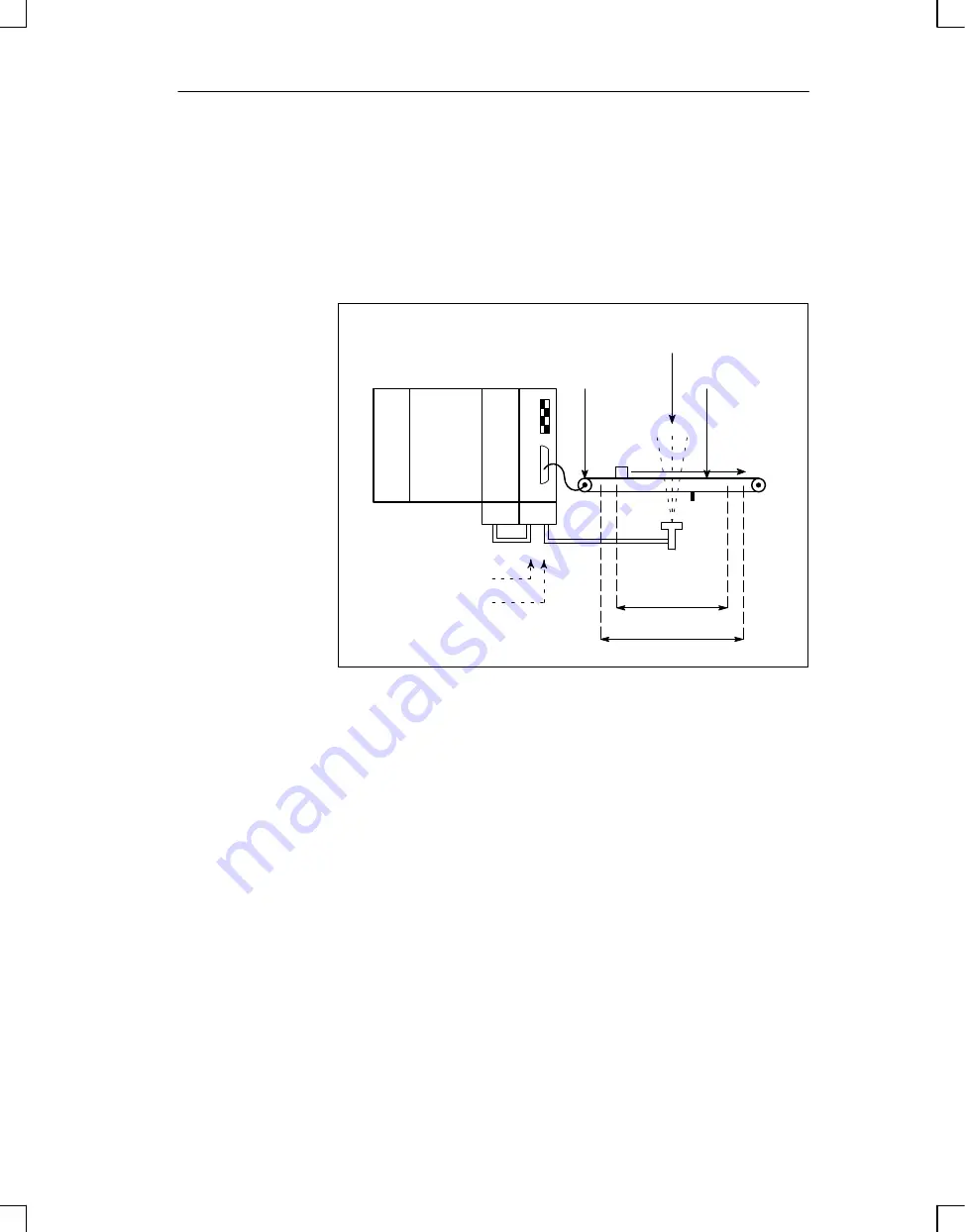

A conveyor belt transports objects from point A to point B. A rotary position

encoder is used, together with a BERO proximity switch as reference trans-

mitter. The conveyor belt is marked at a definite point. As soon as this mark

comes within the range of the BERO, the BERO produces a reference signal.

Following the reference point approach, the enable input is set via a digital

output module (see Figure 9-20).

IM 318–B

DA

PS

Enable Input

Reference Input

Traversing Path

Traversing Range

Rotary Position

Encoder

Operation Range of

Reference Transmitter

Conveyor Belt

Counting–UP

Direction

Mark

BERO

A

B

Figure 9-20 Schematic of a Reference Point Approach Operation

Example

Function Modules