Figure 2-2

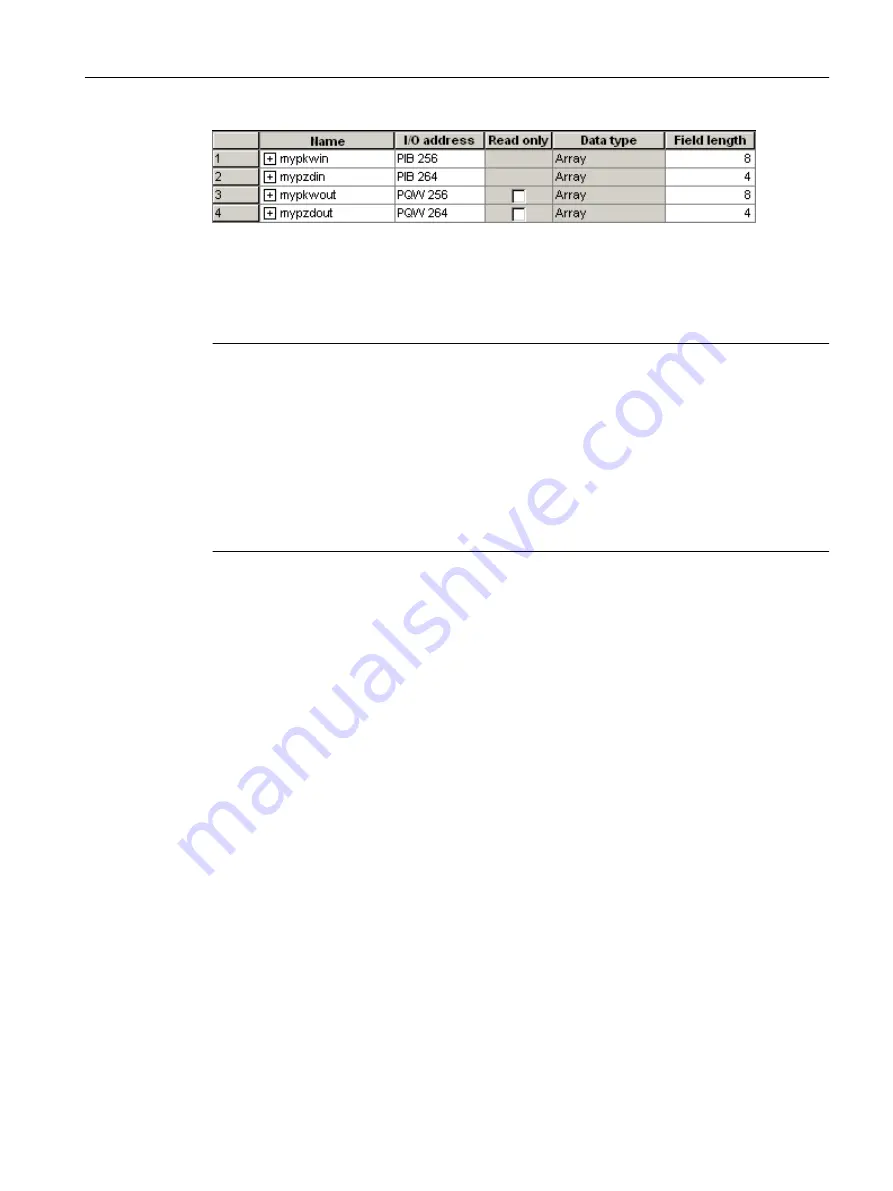

Address assignment in SIMOTION SCOUT

Each input and output address has a range of 8 bytes (which corresponds to the parameter

identifier value (PKW) range of POSMO A) and a range of 4 bytes (which corresponds to the

process data (PZD) range of POSMO A).

Note

For additional information, refer to:

●

SIMOTION SCOUT online help

● Programming Manual of the corresponding programming language, e.g.:

–

SIMOTION ST, Structured Text Programming Manual

–

SIMOTION MCC, Motion Control Chart Programming Manual

–

SIMOTION LAD/FBD, Ladder Diagram and Function Block Diagram Programming

Manual

These documents are shipped with SIMOTION SCOUT in electronic form!

Description

2.5 Creating I/O Variables

Supplement to SIMODRIVE POSMO A Positioning Motor

Function Manual, 01/2015

15