7. Thoroughly suck (or blow) out the brush dust which has settled.

8. Check that all brush holders are correctly closed.

9.1.9

Setting the brush rocker and brush holder

1. After you have replaced the carbon brushes, make sure that you adjust the brush rocker

exactly.

You will find a line on the bearing shield and on the brush rocker itself for this purpose. The

rocker is positioned correctly when both marks are lined up. The marking can be viewed

from one of the service openings.

2. Bolt the brush rocker.

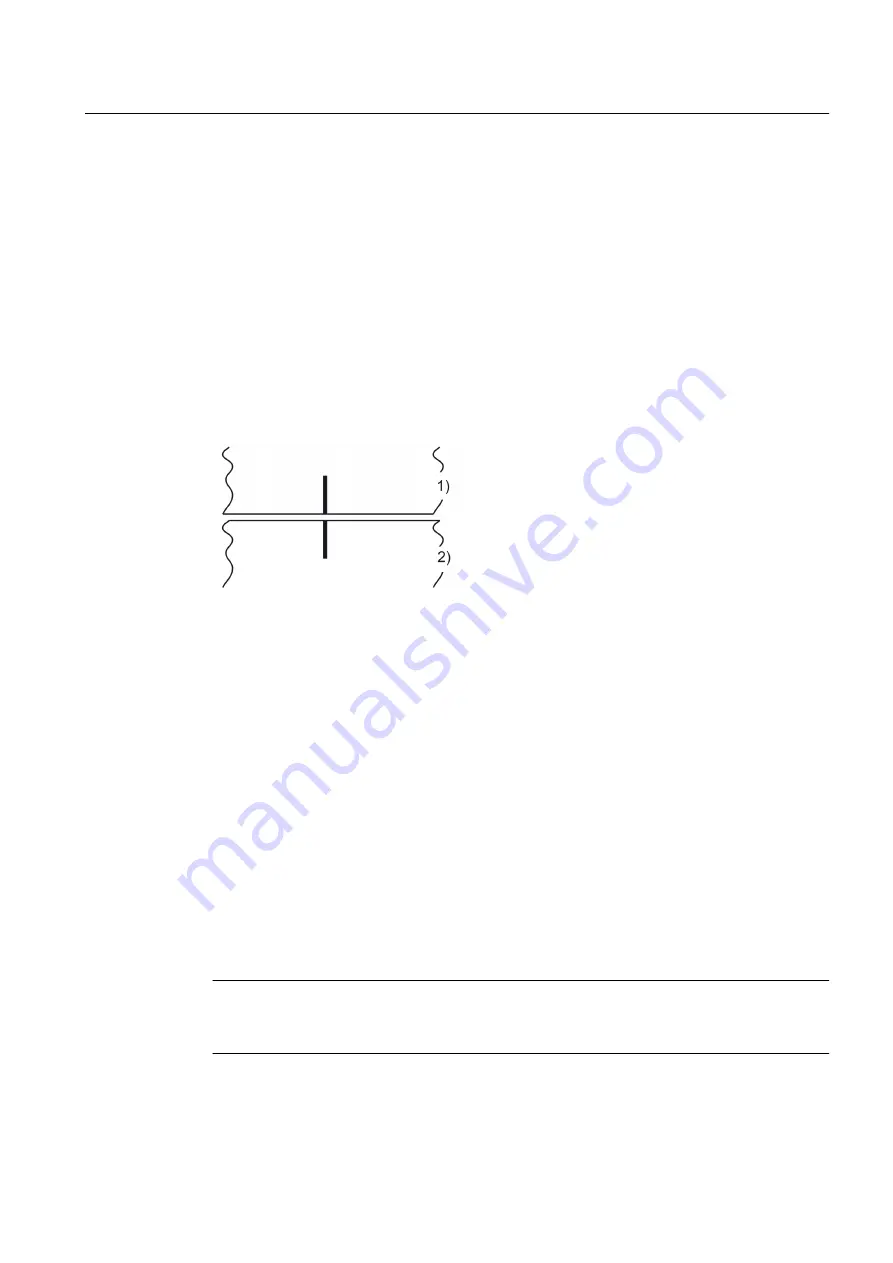

Image 9-1

Adjusting the brush rocker: fixed part (1), brush rocker (2)

Adjusting the brush holders

1. Check the radial clearance between the commutator and the lower edge of the brush holder.

The setting clearance is steplessly adjustable and between 1.5 and 2 mm. The brush holder

can be set inside the machine.

9.1.10

Maintaining the commutator

Cleaning the commutator

● To remove oil, grease and/or dust, clean the commutator with a non-linting cloth .

● Clean the slots between the commutator segments with a suitable wooden slat or glass

pencil.

Note

Sparking or flashover caused by unclean slots

Dirty slots can cause sparking or flashovers on the commutator.

Maintenance

9.1 Inspection and maintenance

SIMOTICS DC 1GG6

Operating Instructions 02/2016

91

Summary of Contents for SIMOTICS DC 1GG6

Page 2: ...08 02 2016 10 27 V4 00 ...

Page 12: ...Table of contents SIMOTICS DC 1GG6 12 Operating Instructions 02 2016 ...

Page 14: ...Introduction 1 1 About these instructions SIMOTICS DC 1GG6 14 Operating Instructions 02 2016 ...

Page 70: ...Commissioning 7 8 Switch off SIMOTICS DC 1GG6 70 Operating Instructions 02 2016 ...

Page 82: ...Operation 8 9 Faults SIMOTICS DC 1GG6 82 Operating Instructions 02 2016 ...

Page 104: ...Maintenance 9 2 Repair SIMOTICS DC 1GG6 104 Operating Instructions 02 2016 ...

Page 138: ...Service and Support SIMOTICS DC 1GG6 138 Operating Instructions 02 2016 ...

Page 142: ...Quality documents SIMOTICS DC 1GG6 142 Operating Instructions 02 2016 ...

Page 153: ......