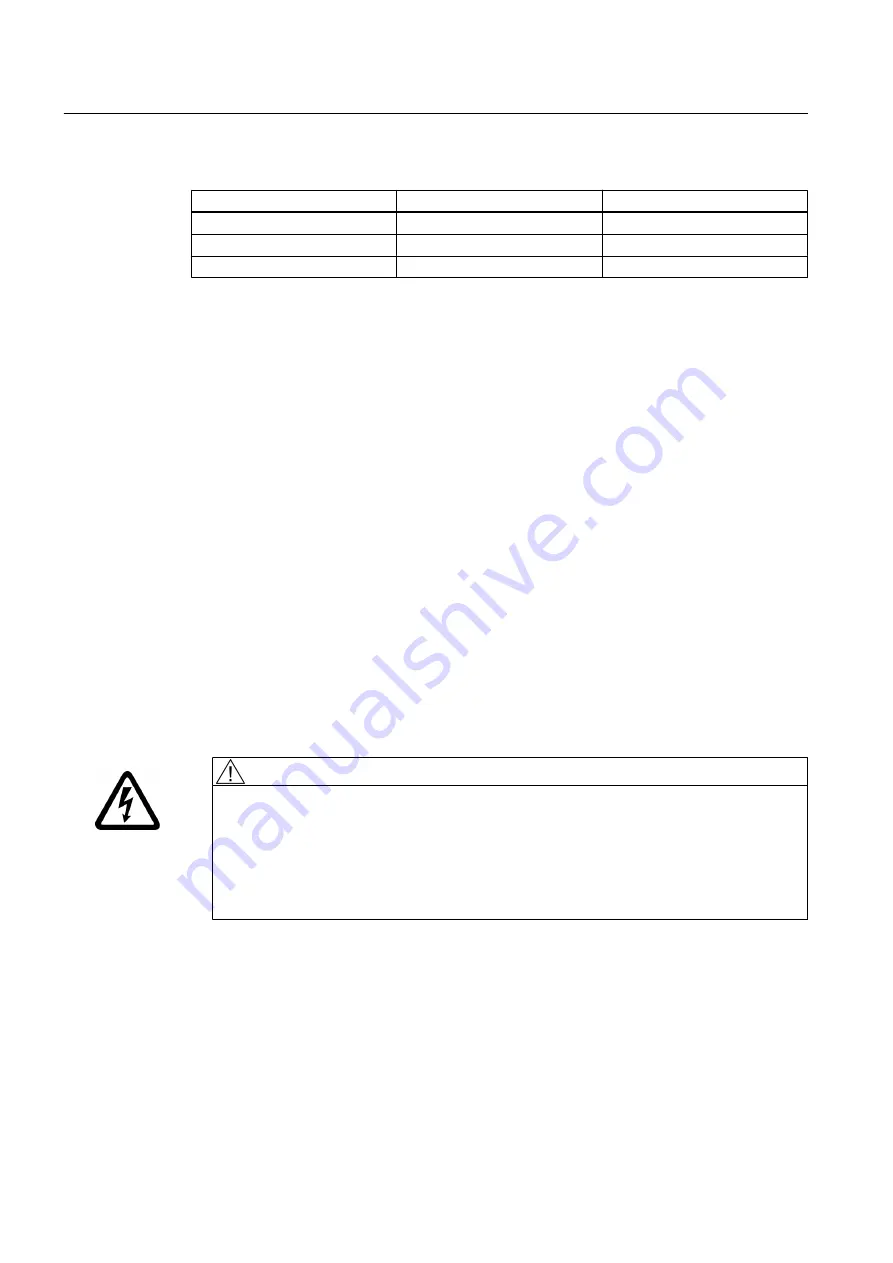

Table 6-4

Tightening torque of screws with ground terminals

Bolt

Screw-in depth

Tightening torque

M6

> 9 mm

8 Nm

M8

> 12 mm

20 Nm

M10

> 15 mm

40 Nm

Equipotential bonding

Terminals are provided on the bearing shield for the connection of an equipotential bonding

conductor.

6.7

Internal equipotential bonding

The equipotential bonding between the protective conductor terminal in the terminal box and

the motor housing is established through the terminal box fixing screws. These screws are

rated and designed as an "equivalent conductive connection" in relation to the protective

conductor cross-section specified for the phase conductor in standard (IEC / EN 60034-1).

Equipotential bonding

In order to guarantee the current carrying capacity of the connection via the retaining bolts in

the event of a short circuit, make sure that the following conditions are fulfilled:

● Use only original gaskets.

● The contact points underneath the bolt heads or spring lock washers must be bare metal

and protected against corrosion.

● The standard cover fixing screws are an adequate equipotential bonding connection

between the terminal box cover and terminal box housing.

WARNING

Electric shock

If the equipotential bonding connection fails, parts of the machine may become live. If you

touch them, you will receive an electric shock. This could result in death, serious injury or

material damage.

When performing any installation work you must always take care to ensure that all

equipotential bonding connections remain effective.

6.8

Connecting the auxiliary circuits

Auxiliary circuit

Terminal strips for cable cross-sections of up to 2.5 mm

2

are provided for connecting auxiliary

circuits, e.g. temperature sensor or anti-condensation heating.

Electrical connection

6.8 Connecting the auxiliary circuits

SIMOTICS DC 1GG6

58

Operating Instructions 02/2016

Summary of Contents for SIMOTICS DC 1GG6

Page 2: ...08 02 2016 10 27 V4 00 ...

Page 12: ...Table of contents SIMOTICS DC 1GG6 12 Operating Instructions 02 2016 ...

Page 14: ...Introduction 1 1 About these instructions SIMOTICS DC 1GG6 14 Operating Instructions 02 2016 ...

Page 70: ...Commissioning 7 8 Switch off SIMOTICS DC 1GG6 70 Operating Instructions 02 2016 ...

Page 82: ...Operation 8 9 Faults SIMOTICS DC 1GG6 82 Operating Instructions 02 2016 ...

Page 104: ...Maintenance 9 2 Repair SIMOTICS DC 1GG6 104 Operating Instructions 02 2016 ...

Page 138: ...Service and Support SIMOTICS DC 1GG6 138 Operating Instructions 02 2016 ...

Page 142: ...Quality documents SIMOTICS DC 1GG6 142 Operating Instructions 02 2016 ...

Page 153: ......