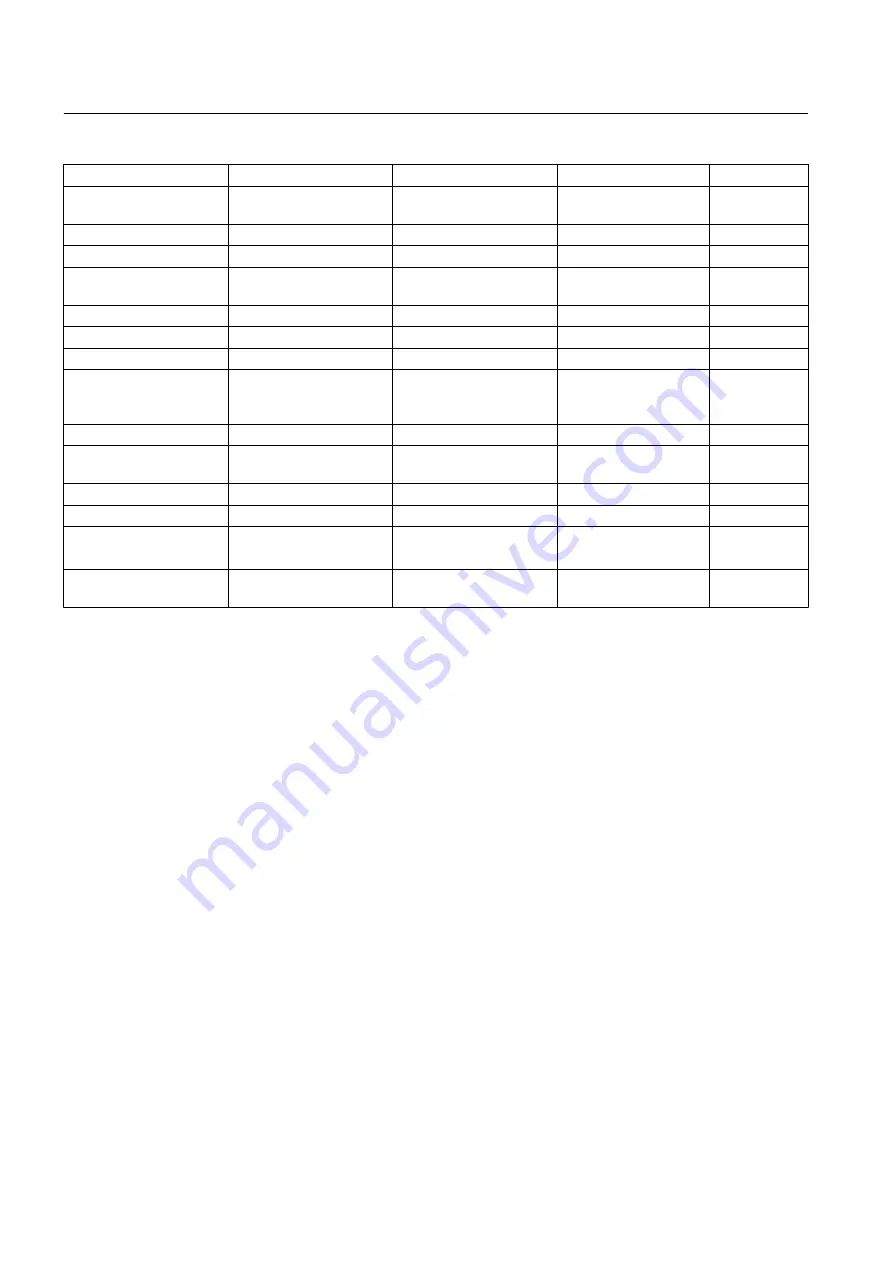

Chloride

Cl

<150 mg/l

DIN 38405-1

ISO 9297

Manganese

Mn

<0.05 mg/l

DIN 38406-2

ISO 6333 /

ISO 11885

Fluoride

F

<0.05 mg/l

DIN 38405-4

ISO 10359-1

Sulfate

SO

4

2-

<150 mg/l

DIN 38405-5

ISO 10304

Copper

Cu = Total copper

<0.1 mg/l

DIN 38406-7

ISO 8288 /

ISO 11885

Silicic acid

SiO

2

<25 mg/l

F1 (DIN 38407-1)

ISO 16264

Free carbon dioxide

CO

2

0 mg/l

G1 (DIN 38408-1)

-

Total salts

<1000 mg/l

DIN 38409-1

-

Nitrate

NO

3

-

<20 mg/l

DIN 38405-9

ISO 7890-1

(Z) /

ISO 10304

Suspended matter

<10 mg/l

DIN 38409-2

ISO 11923

Permanganate consump‐

tion

O

<12 mg/l

H4 (DIN 38409-5)

ISO 8467

Total hardness

Mg+Ca

<12 °DH

DIN 38409-6

ISO 6059

Carbonate hardness

HCO

3

-

<12 °DH

DIN 38404-10

ISO 9963-1

Ammonium content

N ISO 11732 /

NH

4

+

ISO 14911

<10 mg/l

DIN 38406-5

ISO 11732 /

ISO 14911

Iron content

Fe = Total iron

<0.2 mg/l

DIN 38406-1

ISO 6332 /

ISO 11885

4.4

Cooling water inlet temperature (water-cooled motor)

The motor has two cooling circuits that can be used to achieve intensive, effective cooling.

● The fan inside the motor provides air circulation between DE and NDE. This cools, in

particular, the stator winding overhang, the magnetic rotor and the bearings.

● The motor housing is designed with a water-cooling system. This allows a high power

density. The coolant flows through a duct that runs in a spiral from the DE to the NDE in

the cooling jacket. The coolant inlet is on the DE, the coolant outlet is on the NDE. Seen

from the shaft end, connection is possible from the right and from the left.

Close the duct provided for cooling on the cooling circuit. The cooling duct geometry is

designed so that the stator power losses are dissipated. Forced air ventilation prevents local

temperature peaks inside the motor. This also draws off the low magnetic losses in the rotor

via the stator.

Ambient and coolant inlet temperature

To prevent the formation of condensation, the coolant inlet temperature for a stationary motor

and still operational cooling system must be higher than the ambient temperature.

T

cooling water

≥ T

ambient

+ 2 °C

The motor is designed in accordance with EN 60034‑1 for operation up to a coolant

temperature of 25 °C, maintaining all motor data. If you operate the motor with a higher coolant

Preparations for use

4.4 Cooling water inlet temperature (water-cooled motor)

SIMOTICS HT Series HT-direct 1FW4...1......A

28

Operating Instructions 11/2018

Summary of Contents for SIMOTICS HT Series

Page 2: ...13 11 2018 16 25 V5 00 ...

Page 10: ...Table of contents SIMOTICS HT Series HT direct 1FW4 1 A 10 Operating Instructions 11 2018 ...

Page 26: ...Description SIMOTICS HT Series HT direct 1FW4 1 A 26 Operating Instructions 11 2018 ...

Page 118: ...Service and Support SIMOTICS HT Series HT direct 1FW4 1 A 118 Operating Instructions 11 2018 ...

Page 122: ...Quality documents SIMOTICS HT Series HT direct 1FW4 1 A 122 Operating Instructions 11 2018 ...

Page 127: ......