Description

2.2 Overview of the motors

SIMOTICS M-1FE2 built-in motors

22

Configuration Manual, 05/2021, A5E50494252B AB

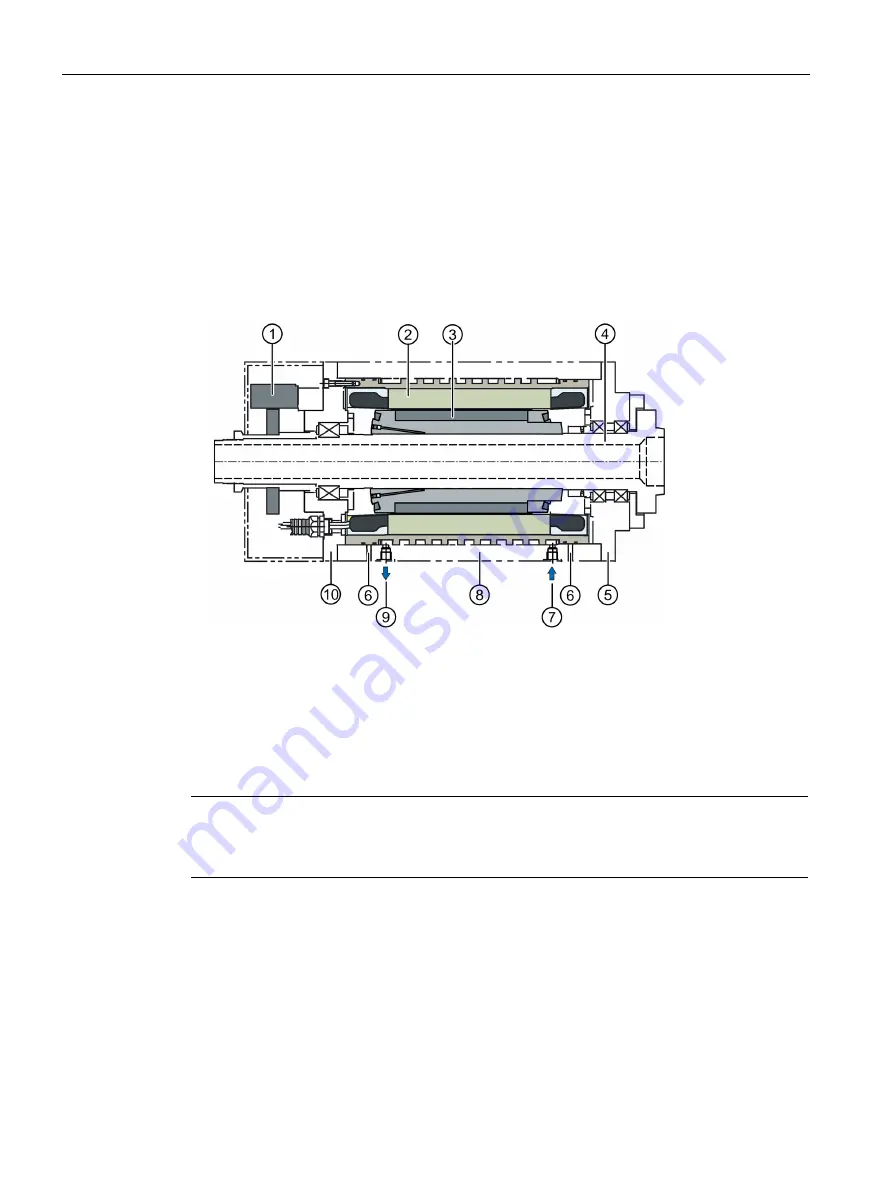

Motor spindle design

A motor spindle comprises the following modules (see the following diagram):

•

Spindle housing

•

Spindle shaft with bearings

•

Built-in motor

•

Cooling system

•

Encoder system

1 Encoder

6 Drain hole

2 Stator with cooling jacket

7 Inlet cooling water connection

3 Rotor with sleeve

8 Spindle housing

4 Spindle shaft with bearings

9 Outlet cooling water connection

5 End shield DE (Drive End)

10 End shield NDE (Non Drive End)

Figure 2-1

Motor spindle design

Note

The spindle manufacturer is responsible for designing the bearings, lubrication and cooling.

A ferritic spindle shaft is a prerequisite in order to achieve the electrical parameters.

Summary of Contents for SIMOTICS M-1FE2

Page 1: ......

Page 2: ......

Page 8: ...Introduction SIMOTICS M 1FE2 built in motors 6 Configuration Manual 05 2021 A5E50494252B AB ...

Page 161: ......

Page 162: ......