Control functions

7.8 Communicating with the PLC

SINAMICS V90, SIMOTICS S-1FL6

288

Operating Instructions, 04/2019, A5E36037884-007

Byte

Description

User data

0001 h

2F1A h

8002 h

0202 h

1001 h

0461 h

0000 h

1001 h

71CA h

0000 h

0801 h

4134 h

7AE1 h

0301 h

0002 h

7,8

9,10

11,12

13,14

15,16

17,18

19,20

21,22

23,24

25,26

27,28

29,30

31,32

33,34

35,36

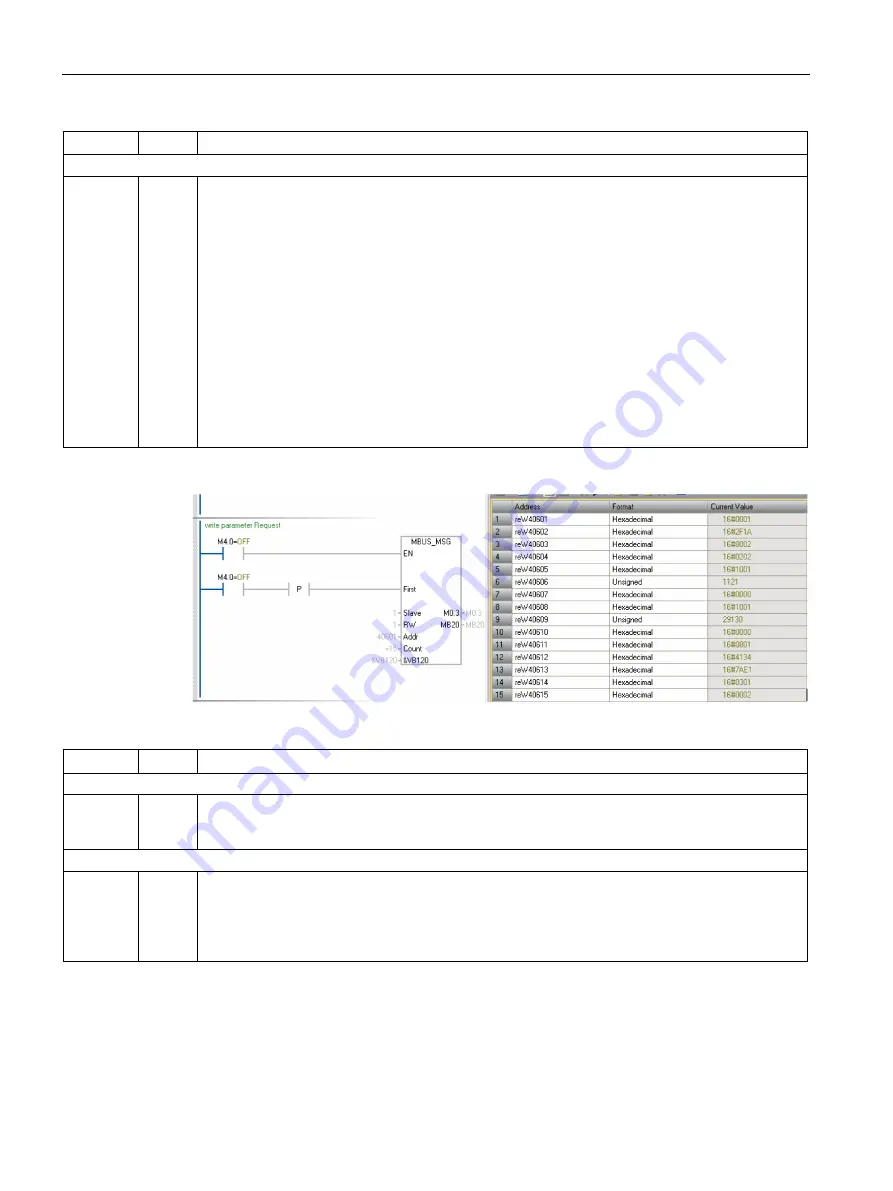

40601: ds47=1 (activate request)

40602: Function 2F h (47), request length 26 bytes (1A h)

40603: Request reference = 80 h, request identifier = 2 h (write)

40604: V90 = 2 h, number of parameters = 2

40605: Attribute, number of elements of the first parameter

40606: First paramter number = p1121

40607: First parameter subindex = 0

40608: Attribute, number of elements of the second parameter

40609: Second paramter number = p29130

40610: Second parameter subindex = 0

40611: Format, number of values of the first parameter

40612: First parameter value 11.28 (41347AE1 h)

40613: First parameter value

40614: Format, number of values of the second parameter

40615: Second parameter value 2

Write the PLC command from registers 40601 to 40615:

The table below formats a response for successful write operation.

Byte

Description

Header

01 h

03 h

20 h

0

1

2

Slave address

Function code (read)

Number of following data bytes (20 h: 32 bytes

≙

16 registers)

User data

0002 h

2F04 h

8002 h

0202 h

3,4

5,6

7,8

9,10

40601: DS47 Control = 2 (request was executed)

40602: Function code 2F h (47), response length 4 bytes

40603: Request reference mirrored = 80 h,

response identifier = 2 (change parameter)

40604: V90 = 2 h, number of parameters = 2