Mounting

5.3 Mounting instructions

SIMOTICS S-1FT2 synchronous motors for SINAMICS S120

Operating Instructions, 07/2021, A5E50610821B AB

51

5.3

Mounting instructions

NOTICE

Damage to the motor due to runout on the shaft extension

Runout and thrust on the shaft extension of the motor can damage the motor.

•

Mount the motor without runout and thrust on the shaft extension.

Note

Note the technical data on the rating plate on the motor frame.

•

Comply with the data on the rating plate, warnings, and notices on the motor.

•

Check the permissible ambient conditions (e.g. temperatures, installation altitude) at the

installation location.

•

Thoroughly clean the shaft extension of corrosion protection. Use commercially available

solvents.

•

Ensure sufficient dissipation of heat. See Chapter "Cooling (Page 40)"

•

If the motor is installed vertically with the end of the shaft facing up, ensure that no liquid

can enter the upper bearing.

•

Ensure that the flange is in even contact with the mounting surface.

•

Use the hexagon socket-head screws, property class at least 8.8.

•

When tightening the fastening bolts avoid any uneven stressing.

•

Observe the tightening torques of the fastening bolts of the motor flange. See table

"Tightening torques for fastening bolts".

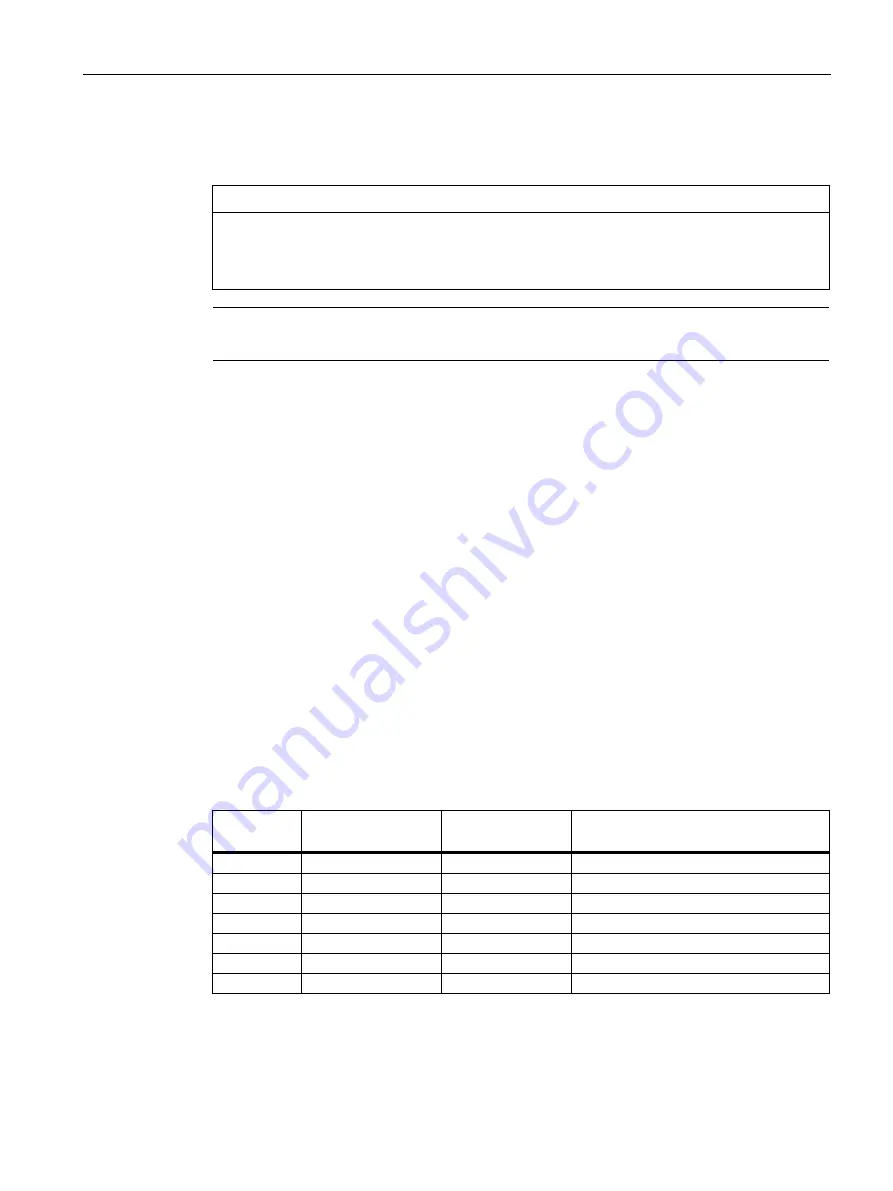

Tightening torques for fastening bolts

The general tolerance for the tightening torque is 10%. The tightening torque is based on a

friction coefficient of μ

= 0.14.

Motor

Bolt DIN 7984

Washer ISO 7092

[mm]

Tightening torque for bolts (not for

electrical connections)

1FT2☐03

M5

5 (d2 = 9)

4 Nm

1FT2☐04

M6

6 (d2 = 11)

8 Nm

1FT2205

M6

6 (d2 = 11)

8 Nm

1FT2105

M8

8 (d2 = 15)

20 Nm

1FT2☐06

M8

8 (d2 = 15)

20 Nm

1FT2☐08

M10

10 (d2 = 18)

35 Nm

1FT2☐10

M12

12 (d2 = 20)

60 Nm

Tightening torques for fastening bolts