3URFHVVLQJF\FOHFORFN

0HDVXULQJ,QSXW72

$[LVH[WHUQDOHQFRGHU

(GJHV

0HDVXULQJLQSXW

70+LJK)HDWXUH

&%%

&31%%

'[;

&\FOLFDOO\PHDVXUHGYDOXHV

,QWKH,32F\FOHFORFN

DWOHDVW

VHUYRF\FOHFORFNV

0HDVXULQJ,QSXW72

$[LVH[WHUQDOHQFRGHU

(GJHV

'['[;;

''

&;&;

&8

0HDVXUHGYDOXHVHYHU\

VHUYRF\FOHV

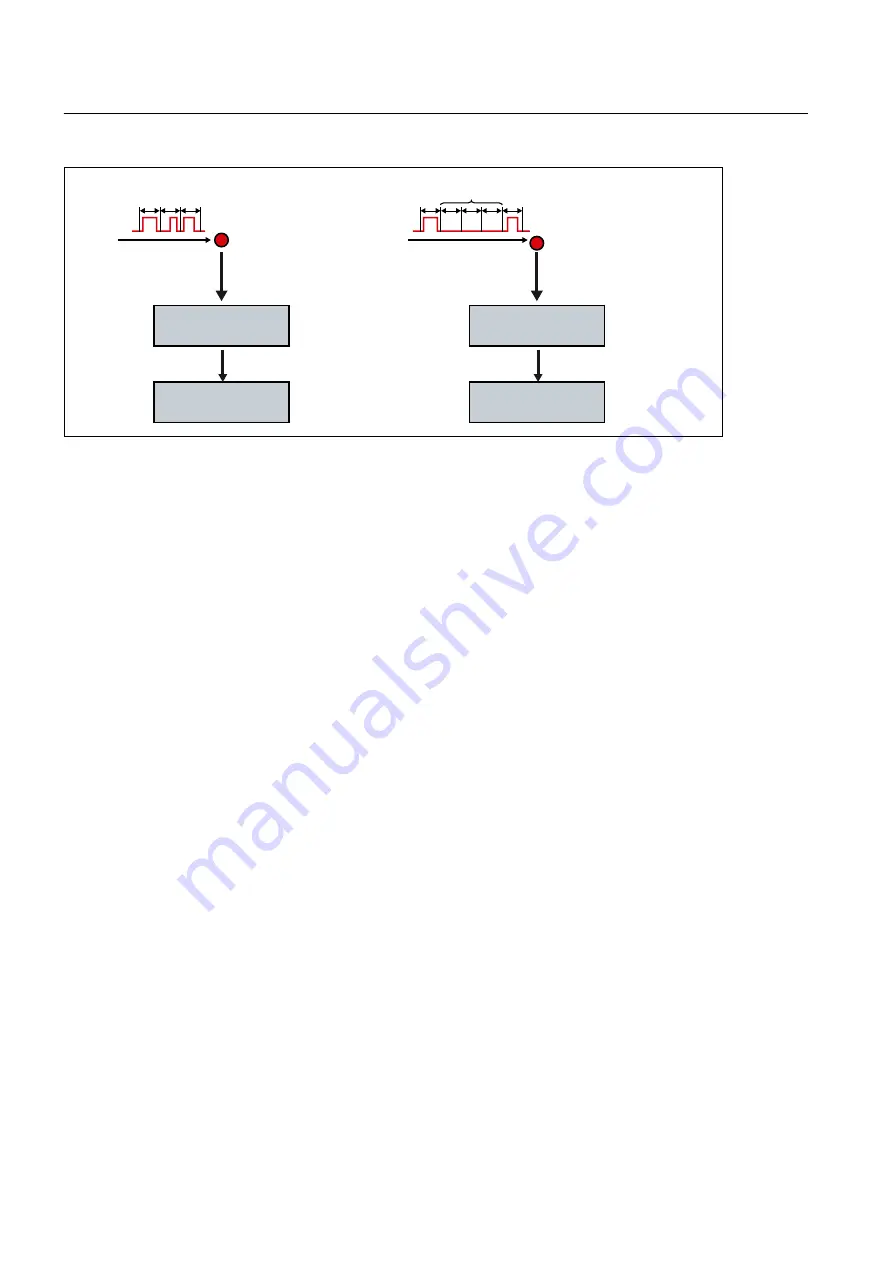

Figure 5-8

Measuring input TO, measuring operation cyclic measurement (example processing cycle clock IPO, no cycle

clock scaling IPO:Servo, IPO = Servo)

Measurement process

A measurement is activated by the _enableMeasuringInputCyclic program command. The

cyclicMeasuringEnableCommand variable indicates the execution status of this command.

The control system variable indicates whether the measuring function is active. Measuring

begins on activation of the program command.

The userdefault.measurededgecyclicMode system variable is used to select which type of

edge should be acquired. Up to two edges can be measured per processing cycle of the

measuring input TO (e.g. IPO interpolation cycle clock, IPO_2 interpolation cycle clock, or

position control cycle clock).

The measured values are taken over in the measurement equipment at time Ti and placed in

the telegram to the control. After that, the measurement equipment is ready again. In the

telegram, two edges per servo can be transmitted to the control. These are provided in a buffer

and processed by the measuring input TO in its processing cycle clock.

With cyclic measuring, the state variable remains in the WAITING_FOR_TRIGGER state even

after the arrival of events, as waiting is continued for further events. Increases on the

countermeasuredvalue1/2 event counter indicate that a measurement event has occurred.

When the measurement event occurs, the measurement position is stored. After successful

measurement, the measured values are stored in the measuredValue1 and measuredValue2

system variables and can be evaluated. The measured values must be read from the user

program before they can be overwritten by a new measurement. For example, if polling is

being performed in the IPO-synchronous task, up to two edges can be evaluated per IPO cycle

clock.

Measuring Input TO - Part III

5.2 Fundamentals of Measuring Input technology object

Output Cams and Measuring Inputs

142

Function Manual, 04/2014