In this case, the measuring input can transfer up to 2 measured value per 1 ms to the TO (that

is, up to 4 in total). The TO can, however, provide the user program with only the first two

measured values via the system variables measuredValue1 and measuredValue2.

counterMeasuredValue1 and counterMeasuredValue2 are each incremented by "1."

In this case, the error condition is signaled synchronously via system variable error and TO

alarm 40009 is output.

Behavior of the count variables counterMeasuredValue1/2

Lost edges can result in the counters counterMeasuredValue1 and counterMeasuredValue2

diverging.

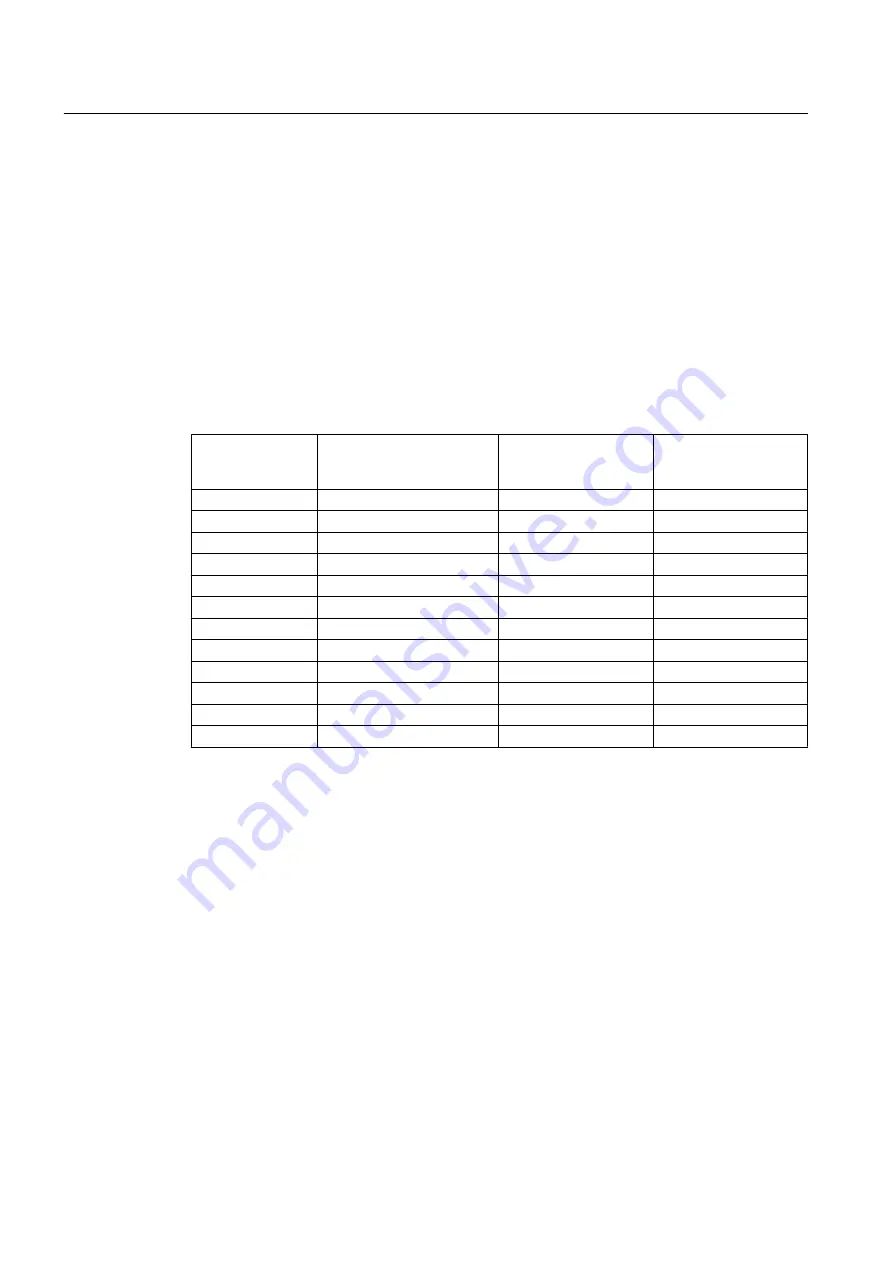

Example: Measurement of rising and falling edges

Processing cycle

clock measuring

input TO

Edges

counterMeasuredValue

1

counterMeasuredValue

2

N

:

:

N+1

6

6

N+2

6

6

N+3

rising-falling

7

7

N+4

rising

8

7

N+5

falling

8

8

N+6

rising-falling-

rising

9

9

N+7

falling

9

10

N+8

rising-falling-

rising

10

11

N+9

falling

10

12

N+10

rising-falling-

rising

11

13

N+11

falling

11

14

*Italics: Edge is lost

Hardware-specific aspects

X142 / Lost Edge Counter

X142 has a counter for lost edges (Lost Edge Counter). Up to 7 lost edges are recorded in

one counter. The counter value is transmitted cyclically and can be symbolically interconnected

in the controller. (LEC). Because the LEC only counts lost edges, for example, only the not

measured "rising" edges are counted in measuring mode "only rising edges."

The LEC only counts the edges that are lost on the X142. Edges lost due to scaling of the

servo cycle clock down to TO processing cycle clock are not acquired by the LEC.

The edges lost on the measuring equipment are only signaled via the LEC. That is, they are

not signaled via system variable/TO alarm.

Via an I/O variable, it is possible to access LEC symbolically and evaluate it in the user program.

Measuring Input TO - Part III

5.2 Fundamentals of Measuring Input technology object

Output Cams and Measuring Inputs

146

Function Manual, 04/2014