You can set the following parameters:

Table 5-7

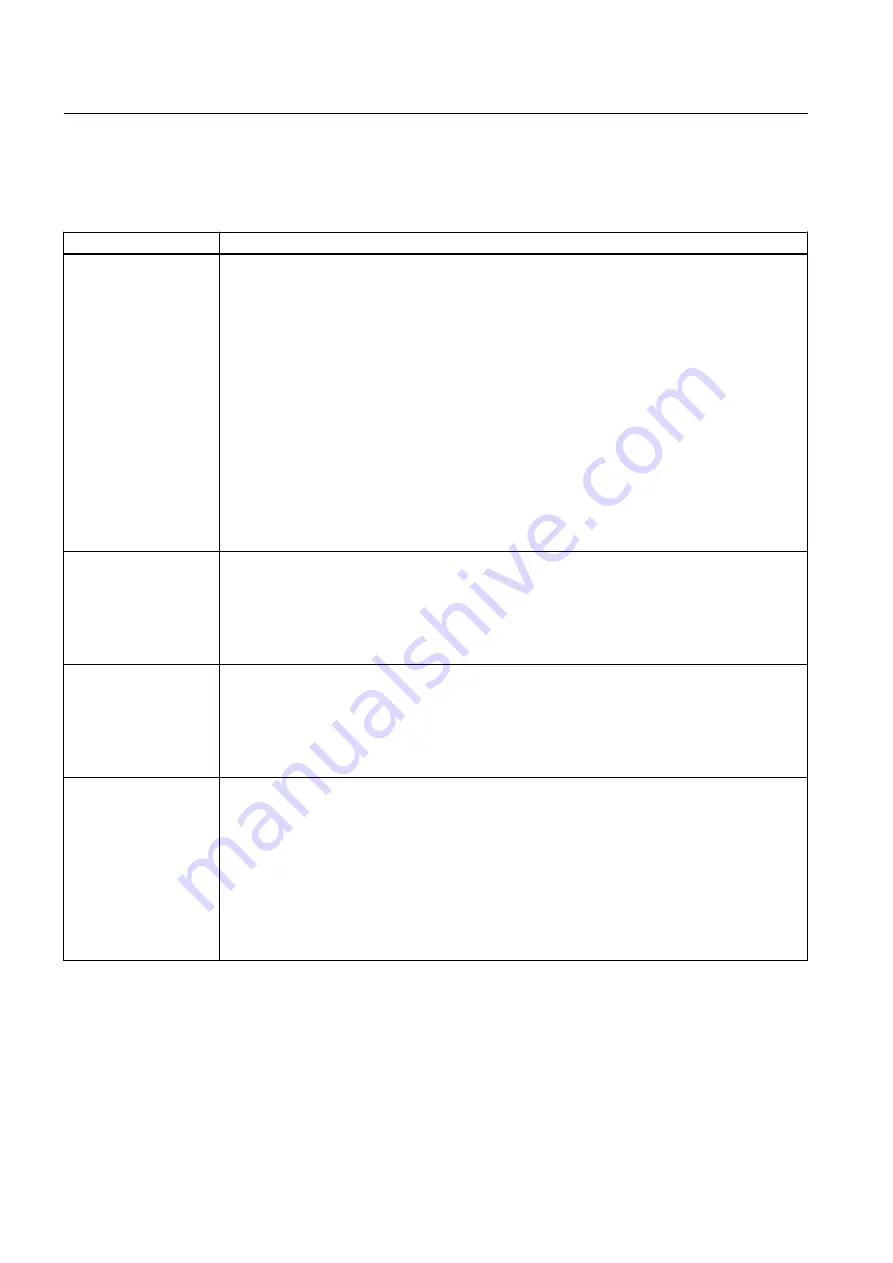

Measuring input defaults

Field/Button

Meaning/information

Edge

(measurement once)

Under Edge you select the signal edge that starts the measurement when present at the measuring

input and measures the actual position of the axis.

The drive must be capable of evaluating the signal edge (rising, falling, or both edges) selected

by SIMOTION at the measuring input.

Rising edge (low to high)

The actual position is recorded with the rising edge of the measuring input.

Falling edge (high to low)

The actual position is recorded with the falling edge of the measuring input.

Measure at both edges

The actual position is recorded using both the rising and falling edge of the measuring input.

Measure at both edges, starting with a rising edge (low to high)

The actual position is recorded using both the rising and falling edge of the measuring input, and

measurement is begun at the first rising edge.

Measure at both edges, starting with a falling edge (high to low)

The actual position is recorded using both the rising and falling edge of the measuring input, and

measurement is begun at the first falling edge.

Start of measuring

range/

End of measuring range

(measurement once)

(See also Chapter

Measuring range)

Enter the start and end of the measuring range here.

If the start of the measuring range is greater than the end of the measuring range for modulo axes,

the measuring range extends from the initial value through the modulo transition to the end value.

For non-modulo axes the initial and end values are swapped in this case.

Measuring range

(measurement once)

(See also Chapter

Measuring range)

Under Measuring range you can choose whether or not to apply the defined measuring range.

Measuring without specified range

The measuring input records the measured values in the entire traversing range.

Measuring in specified range

The measuring input only records the measured values within the measuring range defined by the

start and end points.

The edges to be detected in cyclic measuring are selected here. Up to two edges can be acquired

cyclically per measuring input processing cycle (IPO interpolation cycle, IPO_2 interpolation cycle,

or servo cycle clock). Cyclic measuring is only possible with certain hardware (see Hardware for

measuring inputs (Page 132)).

All edges

Both rising and falling edges are measured.

Rising edges only

Only rising edges are measured.

Falling edges only

Only falling edges are measured.

See also

Measuring Input TO - Part III

5.3 Configuring the Measuring Input technology object

Output Cams and Measuring Inputs

162

Function Manual, 04/2014