Advanced commissioning

6.9 Conveyor technology control functions (for G115D PROFINET and AS-

i variants only)

SINAMICS G115D distributed drive

Operating Instructions, 12/2020, FW V4.7 SP13, A5E48681219B-002

195

6.9.3.1

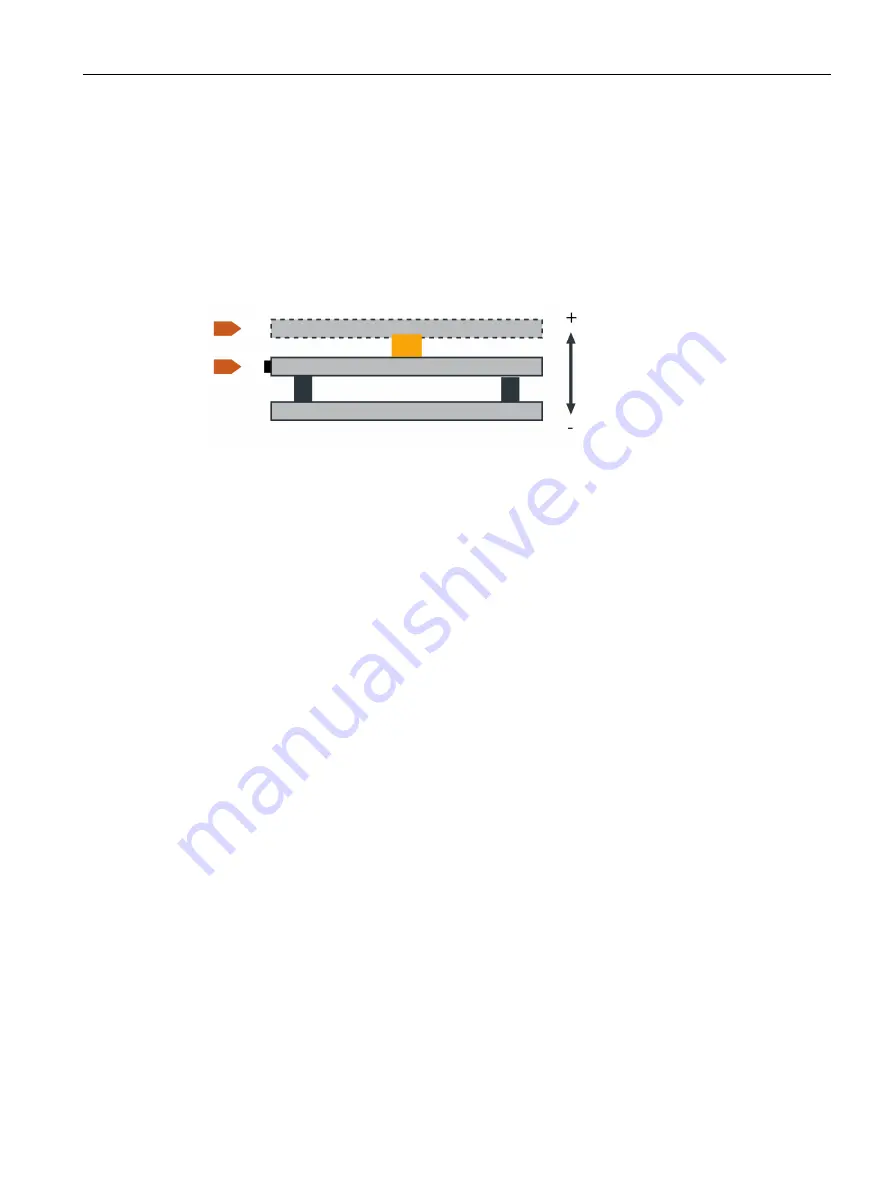

Corner turntable lift, two positions and one speed (p3393 = 9)

Overview

With p3393 (conveyor technology application) set to 9, the converter enables a corner

turntable lift in a conveyor system to move up and down with a fixed speed and stop at two

dedicated positions. Two sensors are required to signal the limit positions for the motor to

stop.

Precondition

•

You interconnect the signals of the sensors with the digital inputs of your choice.

•

To make sure that the corner turntable lift moves between the higher position and the

lower position, the end position shutdown must be activated with p3392 set to 1.

Function description

•

With the ON command, the motor accelerates to its speed setpoint (p1070). The lift

moves in either positive or negative direction depending on the setting of p1113:

–

p1113 = 0: positive direction

–

p1113 = 1: negative direction

•

With the end position shutdown deactivated (p3392 = 0), the following applies:

–

The motor stops with OFF1 ramp when either of the two stop sensors (p3384 and

p3385) is triggered (level/edge triggered depending on p3394).

–

With the sensor evaluation type (p3394) set to 1 or 2 (level triggering), the motor

starts again in either positive or negative direction when the level is canceled; with

p3394 set to 3 or 4 (edge triggering), a new ON command must be initiated to start

the motor again in either positive or negative direction.

–

Setting the sensor bypass signal (p3390) to 1 overrides the sensor signals p3384 and

p3385.