Setting Up

SINUMERIK 801

5

-13

Start-Up

4.7 Starting Up the Spindle

General

Spindle can come in two types: contactor-controlled spindle and analog

spindle. For analog spindle, through setting up the spindle, the machine tool

can have various functions such as thread machining, constant cutting speed,

programming spindle speed limit, etc.

Parameterization

If an AC motor and inverter or a servo spindle is used, when machining a

thread or programming it based on the feedrate per revolution, set

MD30130 = 1.

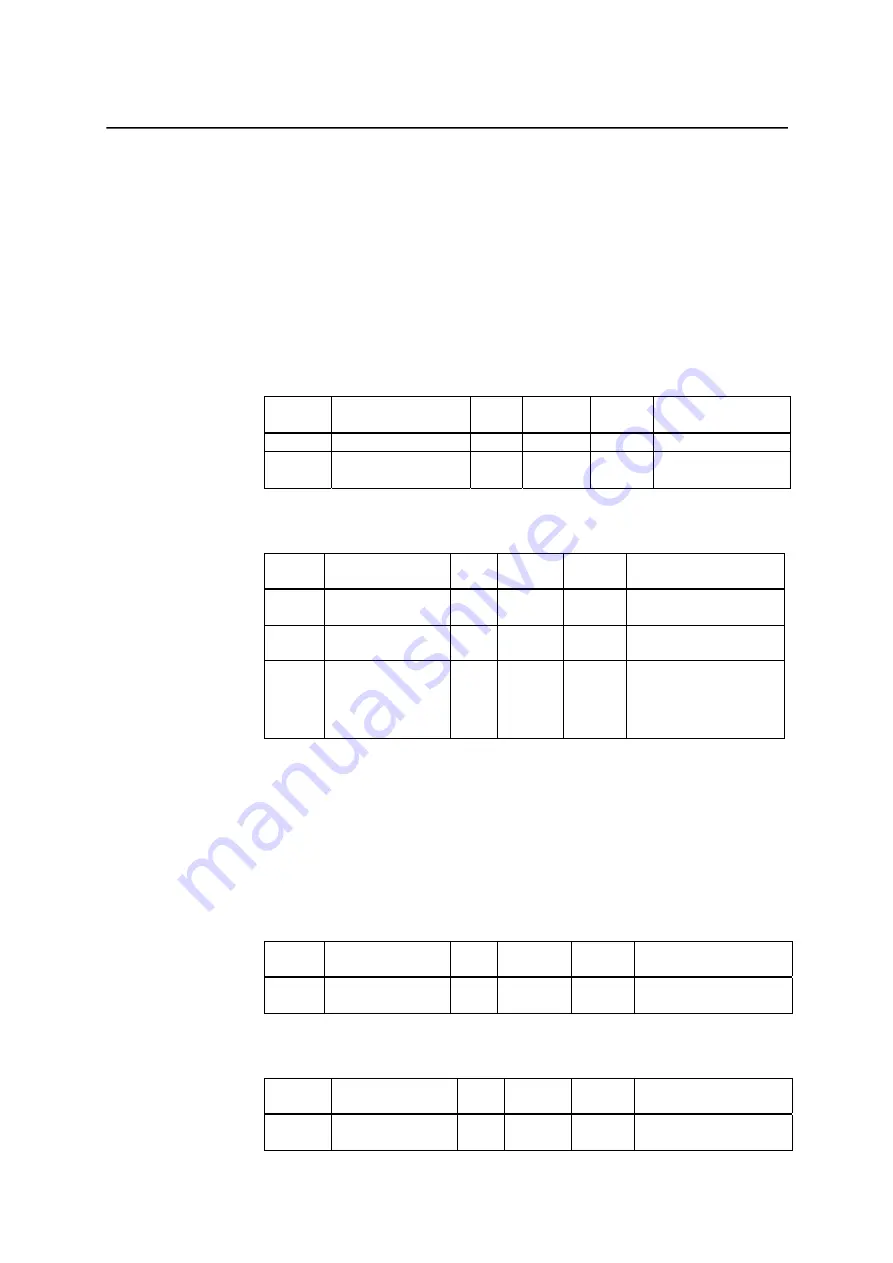

MD Designation

Unit

Axis

Input

value

Description

30130

CTRLOUT_TYPE

-

Spindle

0

No analog output

30130 CTRLOUT_TYPE

- Spindle

1

±

10VDC analog

output

Set the machine spindle outputs as unipolar/bipolar setpoint output.

MD Designation Unit

Axis

Input

value

Description

30134 IS_UNIPOLAR_

OUTPUT

-

Spindle

0

Setpoint output is

bipolar

30134 IS_UNIPOLAR_

OUTPUT

- Spindle

1

*

Setpoint output is

unipolar

30134 IS_UNIPOLAR_

OUTPUT

- Spindle

2

*

Setpoint output is

unipolar

,

Q0.0 and

Q0.1 can not be

recalled by PLC;

* When MD30134 =1: Q0.0

=

Servo enable;

Q0.1

=

Spindle CCW

MD30134 =2: Q0.0

=

Sevo enable, spindle CW;

Q0.1

=

Servo enable, spindle CCW

If the spindle has no encoder feedback, set MD30200 = 0.

MD Designation Unit

Axis

Input

value

Description

30200 NUM_ENCS

-

Spindle

0 Spindle without

encoder

When producing a thread, configure the spindle with an encoder:

MD Designation

Unit

Axis

Input

value

Description

30240 ENC_TYPE

-

Spindle

2 Spindle

with

measuring system

Summary of Contents for Sinumerik 801

Page 1: ...Start Up 11 2005 Edition sinumerik SIEMENS SINUMERIK 801 ...

Page 6: ......

Page 8: ......

Page 16: ......

Page 78: ......

Page 81: ...Services Diagnosis and Data Saving SINUMERIK 801 5 3 Start Up Fig 5 4 ...

Page 105: ...A5E00702069 ...