PLC commissioning

6.5 Creating a PROFIBUS configuration

Manual

178

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0

6,0$7,&0DQDJHU6,1'LVO

)LOH(GLW,QVHUW7DUJHW9LHZ6\VWHP7RROV:LQGRZ+HOS

6,1'LVO,QVWDOODWLRQSDWK!?6WHS?63URM?6,1'LVO

6,1'LVO

6,0$7,&

3/&'3$-

63URJUDP

6RXUFHV

0RGXOHV

2%

JS[GI

JS[G

6RXUFHV

0RGXOHV

2%2%2%)%

)%)%)%)%

)%)%)%)%

)%)%)%)%

1R)LOWHU!

JS[G)?6LHPHQV?6WHS?6OLEV?JS[G

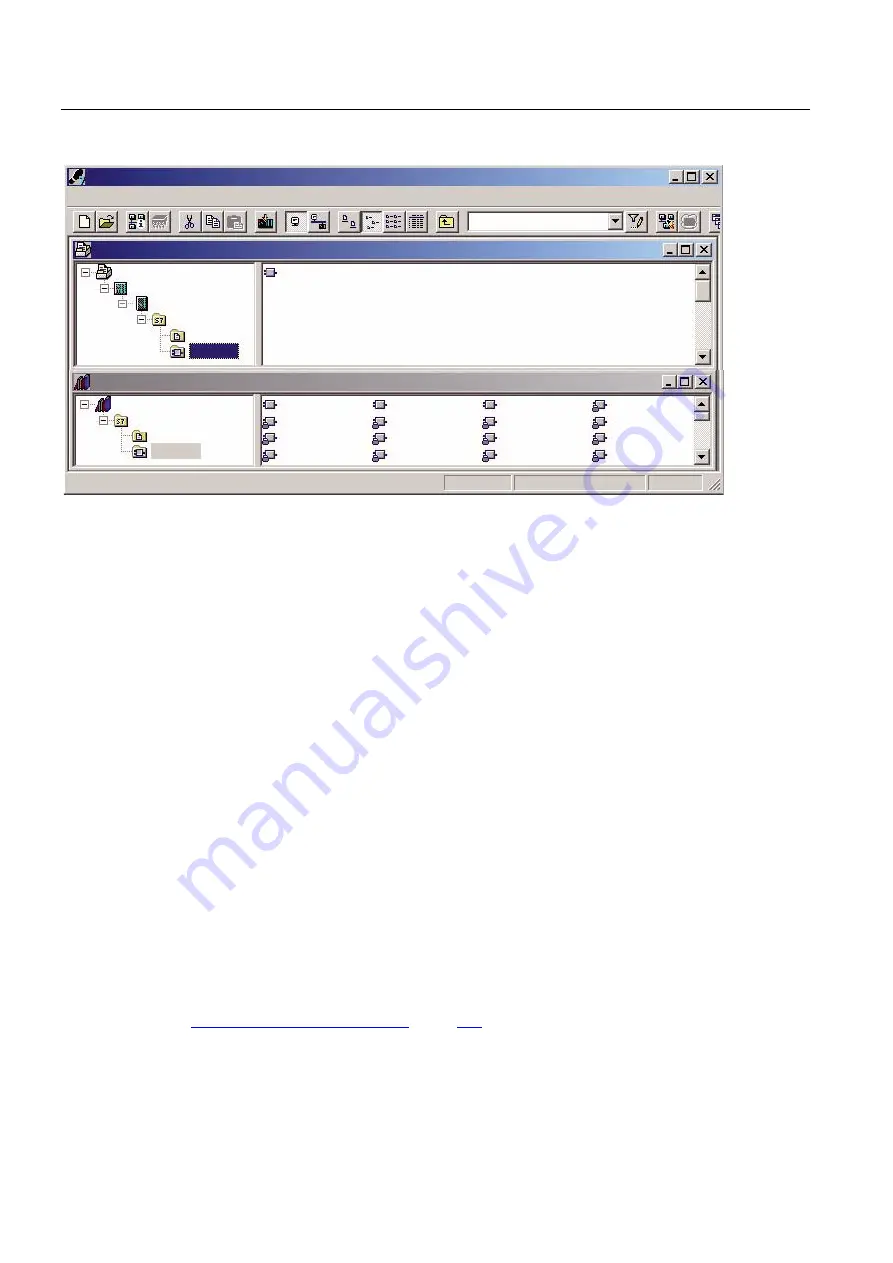

Figure 6-9

Inserting blocks of the PLC basic program

Overwrite OB1

Inserting blocks overwrites the existing organization block OB1. Confirm the query as to

whether you want to overwrite the block with "Yes".

6.4.2

PLC user program

The PLC user program according to its definition contains all functions required to process

user-specific automation tasks. Tasks of the PLC user program include:

●

Defining the conditions for a restart (warm restart) and PLC restart.

●

Processing process data, for example, combining signals, reading in and evaluating

analog values, defining signals for output and outputting analog values.

●

Responding to alarms

●

Error handling in normal program execution

The basis of the PLC user program is the PLC basic program already included in the S7

project. Now expand and alter the PLC basic program to suit your automation task.

6.5

Creating a PROFIBUS configuration

Creation of a PROFIBUS configuration is described in a separate section. See Chapter