NC Commissioning with HMI Advanced

11.5 Axes and spindles

Manual

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0

385

11.5

Axes and spindles

11.5.1

Axis configuration

Definition

The term "axis" is often used either as a single term in conjunction with SINUMERIK 840Disl

or in a compound form, e.g. machine axis, channel axis, etc. To provide an overview of the

philosophy used as the basis, here is a brief explanation of this term.

There are basically 3 types of axes:

1.

Coordinate axes

2.

Machine axes

3.

Geometry and special axes

Coordinate axes

Coordinate axes (abscissa, ordinate, applicate) are the axes of a Cartesian coordinate

system

Machine axes

Machine axes are the motion units existing on a machine, which can also be designated as

linear or rotary axes, depending on their usable movement.

Geometry axes

The geometry axes constitute the rectangular Cartesian basic coordinate system of a

channel.

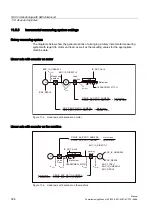

Generally, (Cartesian arrangement of the machine axes) direct imaging of the geometry axes

to the machine axes is possible. If the arrangement of the machine axes, however, is not

Cartesian at right angles, the imaging is performed using a kinematic transformation.

Special axes

Special axes are all axes of a channel that are not geometry or machine axes. Unlike for

geometry axes (Cartesian coordinate system), no geometric context is defined for additional

axes, neither between additional axes or with respect to geometry axes.

Channel axes

The total of all machine, geometry and special axes assigned to a channel is designated as

channel axes.

The geometry and special axes represent the programming side of the machining process,

i.e. they are used for programming in the part program.

The machine axes constitute the physical part of the machining process, i.e. they carry out

the programmed traversing movements on the machine.