NC Commissioning with HMI Advanced

11.5 Axes and spindles

Manual

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0

411

Interface signals

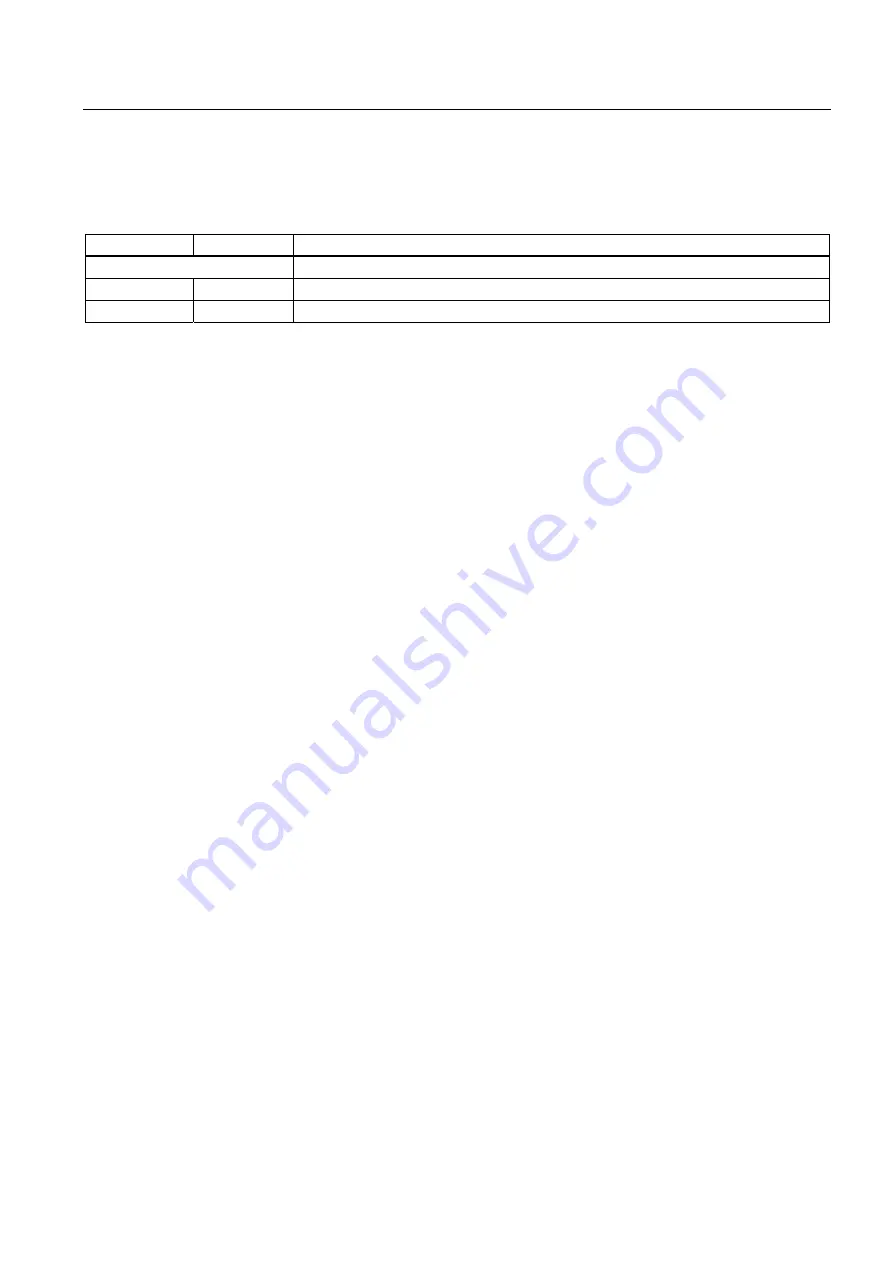

Table 11-30 Indexing axes: Interface signals

DB number

Bit, byte

Name

Axis/spindle-specific

Signals from axis/spindle to PLC

31,...

60.4, 60.5

Referenced/synchronized 1, referenced/synchronized 2

31,...

76.6

Indexing axis in position

References:

/FB/ Function Manual, Extended Functions,T1 Indexing axes

11.5.13

Parameter sets of axis/spindle

Per machine axis, six parameter sets are available. They serve the following purpose:

●

on an axis:

for accommodation of the own dynamic response to another machine axis, e.g. when

tapping or thread cutting on the relevant spindle.

●

on a spindle:

for accommodation of the position controller to modified properties of the machine during

operation, e.g. when switching the gearbox.

Tapping, thread cutting

The following applies to axes:

●

For a machine axis that is not involved in tapping or thread cutting, the 1st set of

parameters (index=0) is active in all cases.

The further parameter sets need not be considered.

●

Machine axes involved in tapping or thread cutting: the parameter set is activated in

accordance with the current gear stage.

All parameter sets must be parameterized in accordance with the gear stages of the

spindle.

The following applies to spindles:

●

With spindles, each gear stage is assigned a parameter set of its own. The parameter set

is selected by the PLC via the interface signal DB31, ... DBX16.0 - 16.2 (actual gear

stage).

All parameter sets must be parameterized in accordance with the gear stages of the

spindle.

For example, in HMI Advanced, the active parameter set of a machine axis is displayed in

the control area "DIAGNOSIS" in the screen form "Service Axis".