NC Commissioning with HMI Advanced

11.5 Axes and spindles

Manual

452

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0

*HDU

0RWRU

HQFRGHU

0RWRU

%(52

&KXFN

3RZHU

FRQQHFWLRQ

0RWRU

HQFRGHU

FDEOH

7RRWKHGEHOW

'ULYH

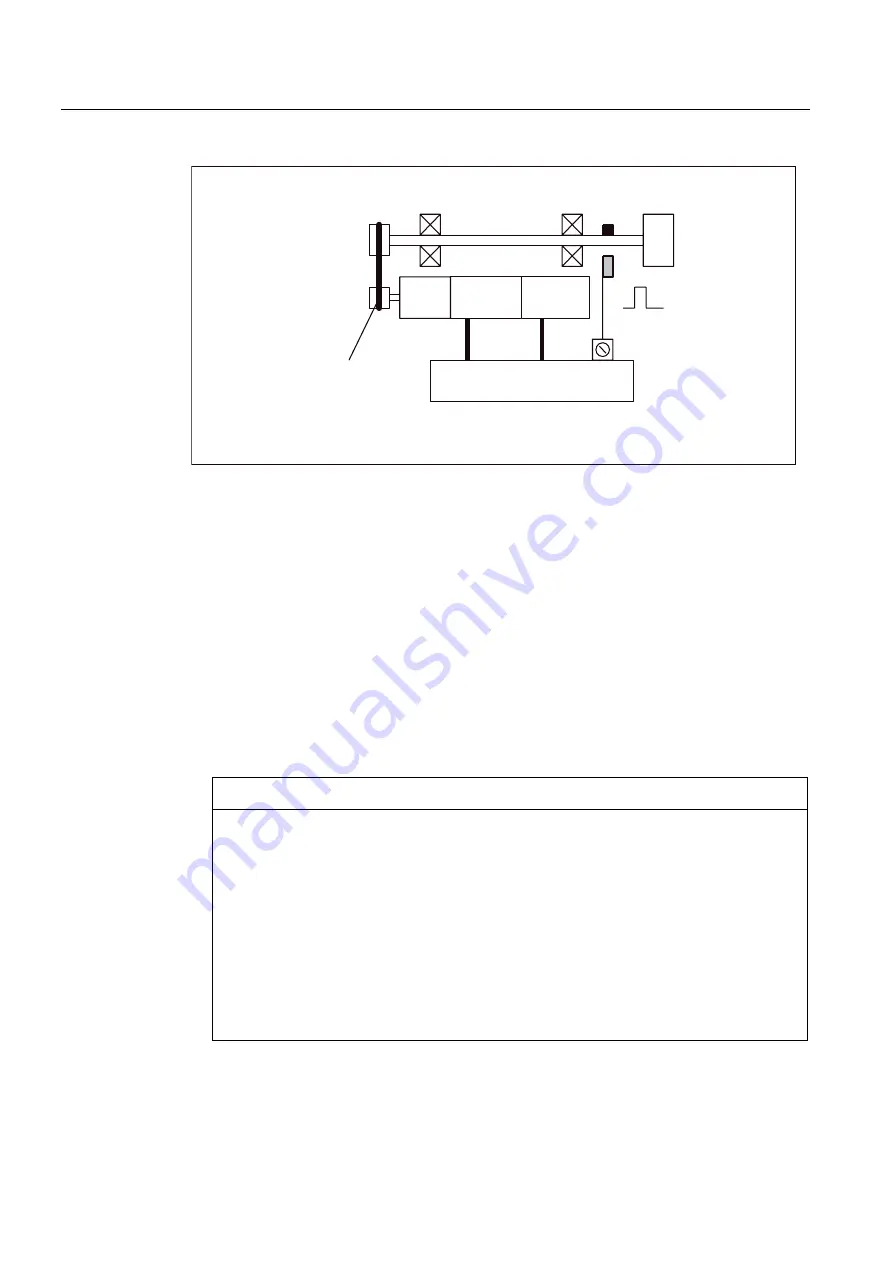

Figure 11-29 Synchronization using BERO

When is synchronization necessary?

The spindle will be synchronized:

●

after the NC has powered up when the spindle is moved using a programming command

●

after a request for resynchronization by the PLC

IS DB31,... DBX16.4 (resynchronize spindle 1)

IS DB31,... DBX16.5 (resynchronize spindle 2)

●

after each gear stage change for an indirect measuring system

MD31040 $MA_ENC_IS_DIRECT (direct measuring system) = 0

●

when the encoder limit frequency falls below the programmed value after a speed has

been programmed which is above the encoder limit frequency.

NOTICE

The following is to be taken into account:

•

To synchronize the spindle, it must always be rotated using a programming

command (e.g. M3, M4, SPOS). The specification of a spindle speed using the

direction keys of the machine control panel is not sufficient.

•

If the spindle encoder is not mounted directly on the spindle and there are speed-

transforming gears between the encoder and spindle (e.g. encoder mounted on

motor), then a reference cam signal connected to the drive module must be used for

synchronization.

The control system then automatically resynchronizes the spindle after each gear

stage change. The user does not have to contribute anything here.

•

In general, backlash, gearbox elasticity and reference cam hysteresis reduce the

accuracy achievable during synchronization.