06.03

10.5 Axes and spindles

10-319

Siemens AG, 2003. All rights reserved

SINUMERIK 840Di Manual (HBI) – 06.03 Edition

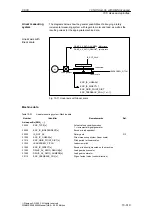

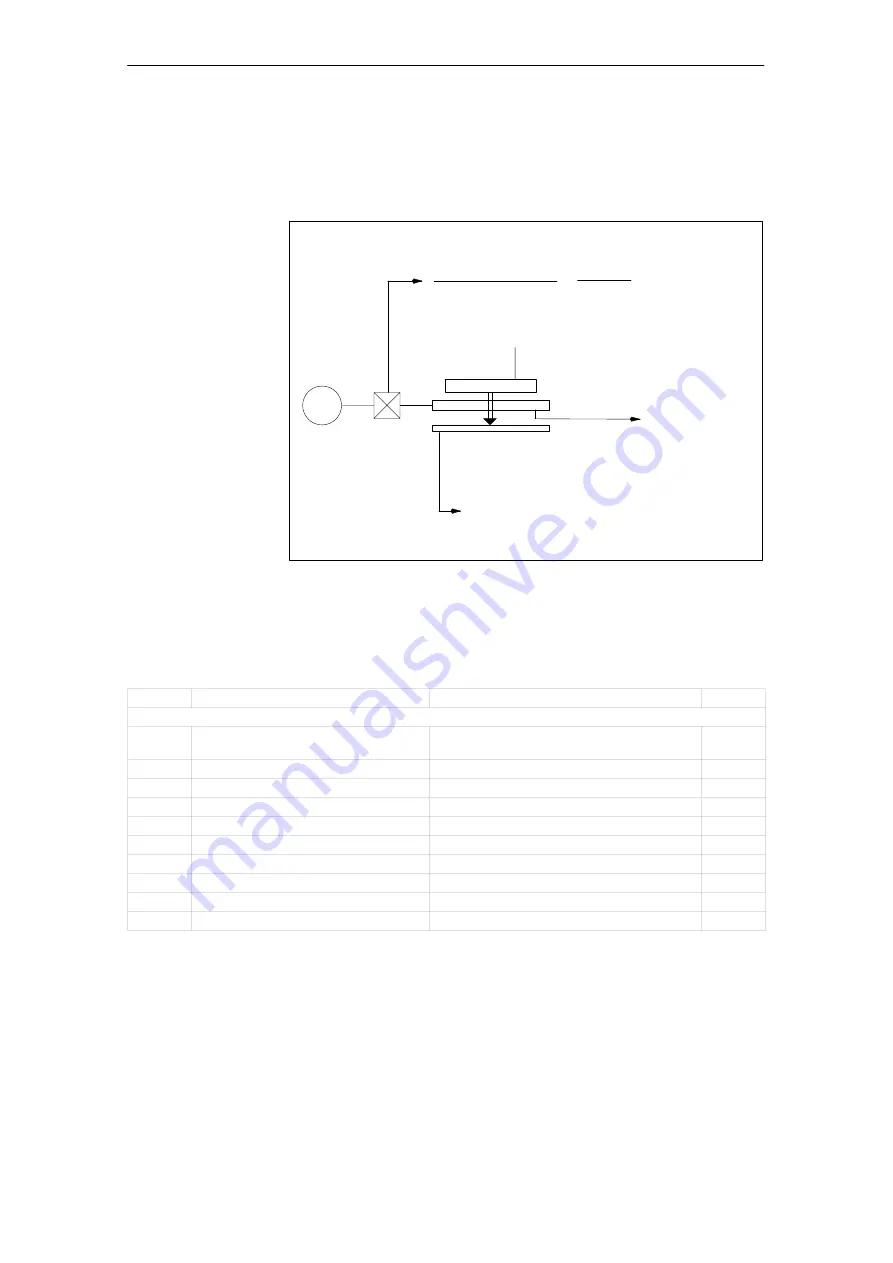

The diagrams below show the general possibilities of arranging a rotary

incremental measuring system with regard to motor and load, as well as the

resulting values for the appropriate machine data.

M

IS_ROT_AX=0

ÍÍÍÍÍÍ

Leadscrew

Load gearbox

Table

Linear scale

ENC_IS_LINEAR=1

ENC_IS_DIRECT=1

ENC_GRID_POINT_DIST

ENC_FEEDBACK_POL= [1 or -1]

DRIVE_AX_RATIO_NUMERA

DRIVE_AX_RATIO_DENOM

LEADSCREW_PITCH

spindle revs

Motor revs

=

Fig. 10-11 Linear axis with linear scale

Table 10-22

Linear measuring system: Machine data

Number

Identifier

Name/remarks

Ref.

Axis-specific ($MA_ ...)

30240

ENC_TYPE[n]

Actual-value acquisition modes

1 = incremental signal generator

30242

ENC_IS_INDEPENDENT[n]

Encoder is independent

30300

IS_ROT_AX

Rotary axis

R2

31000

ENC_IS_LINEAR[n]

Direct measuring system (linear scale)

31010

ENC_GRID_POINT_DIST[n]

Pitch period for linear scales

31030

LEADSCREW_PITCH

Leadscrew pitch

31040

ENC_IS_DIRECT[n]

Encoder is directly mounted on the machine

31050

DRIVE_AX_RATIO_DENOM[n]

Load gear denominator

31060

DRIVE_AX_RATIO_NUMERA[n]

Load gear numerator

32110

ENC_FEEDBACK_POL[n]

Sign of actual value (control direction)

Linear measuring

system

Linear axis with

linear scale

Machine data

10 NC Start-Up with HMI Advanced