06.03

10.5 Axes and spindles

10-351

Siemens AG, 2003. All rights reserved

SINUMERIK 840Di Manual (HBI) – 06.03 Edition

10.5.19 Referencing an axis

When referencing a machine axis, the actual position value system of the ma-

chine axis is synchronized with the machine geometry.

Depending on the encoder type used, the machine axis is referenced with or

without traversing movements.

For all machine axes which are not equipped with an encoder providing an ab-

solute actual position value, referencing is carried out by traversing the machine

axis, the so-called reference point approach.

The reference point approach can be carried out either manually in JOG mode,

submode REF, or using a parts program. Reference point approach is started

using traversing keys PLUS or MINUS (depending on the parameterized refer-

ence point approach direction).

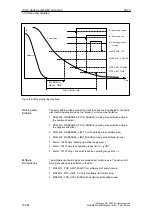

With incremental measuring systems, referencing is carried out using a

reference point approach divided into 3 phases:

1. Traversing to the reference cam

2. Synchronizing to the encoder zero marker

3. Approach reference point.

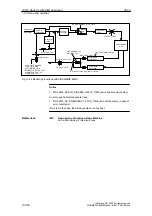

The following machine data and interface signals are independent with re-

spect to the individual phases of reference point approach:

MD11300: JOG_INC_MODE_LEVELTRIGGRD (INC/REF in jog mode)

MD34000: REFP_CAM_IS_ACTIVE (axis with reference cam)

MD34110: REFP_CYCLE_NR (axis sequence with channel-specific refer-

ence point approach)

MD 30240: ENC_TYPE (encoder type)

Set MD 34200: ENC_REFP_MODE (referencing mode)

IS: DB21, ... DBX1.0 (“Activate referencing”)

IS: DB21, ... DBX33.0 (“Referencing active”).

Referencing

Reference point

approach

Incremental

measuring

systems

Phase-independent

data

10 NC Start-Up with HMI Advanced