06.03

10.10 NC/PLC diagnosis (840Di SW 2.3 and higher)

10-398

Siemens AG, 2003. All rights reserved

SINUMERIK 840Di Manual (HBI) – 06.03 Edition

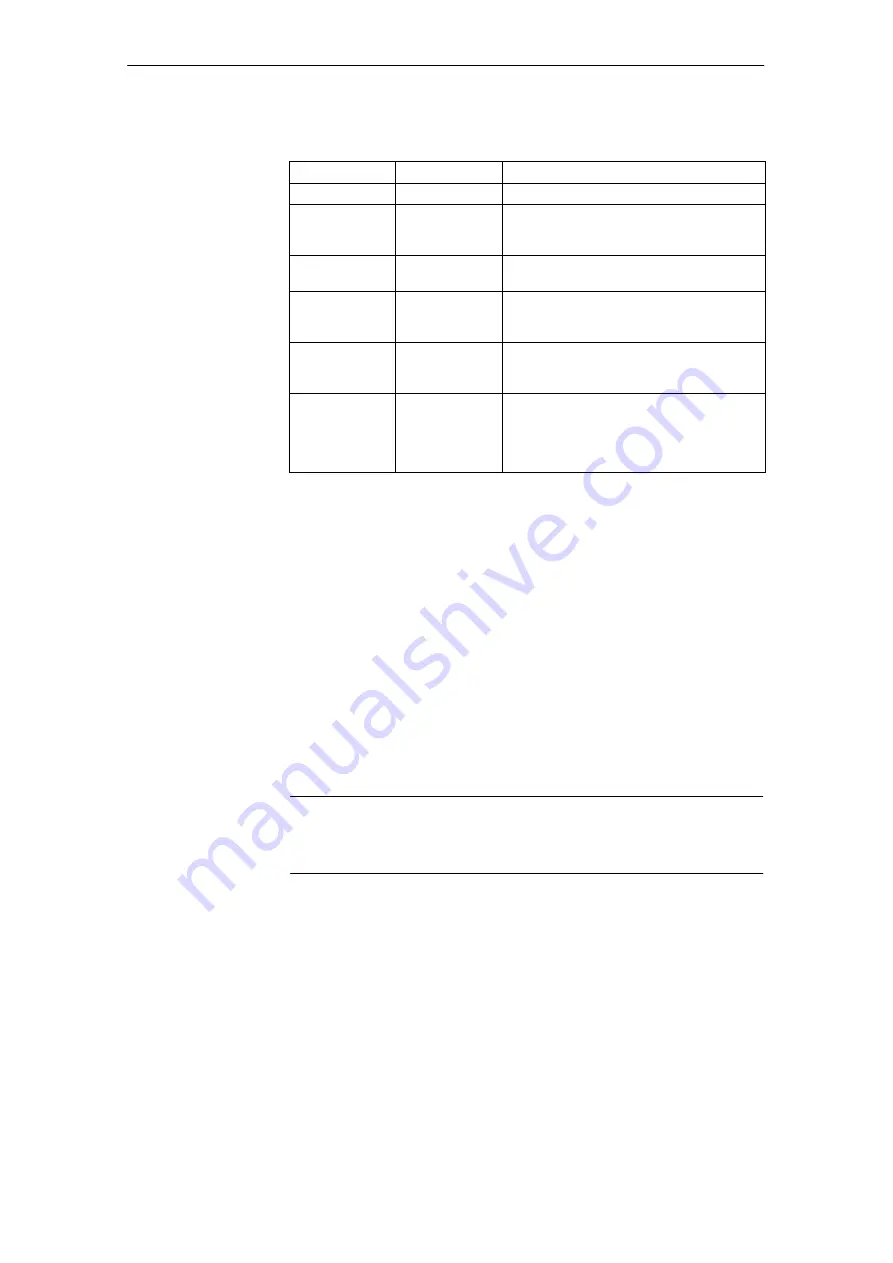

Table 10-54

PLC operating state display per RUN/STOP evaluation

RUN

STOP

PLC operating state

lit

off

RUN The PLC program is running.

off

lit

STOP: The PLC program is not running. STOP

can be triggered by the PLC program, by an er-

ror or per user operation.

Flashes at 0.5 Hz

lit

HOLD: The PLC user program was halted (trig-

gered by a test function).

Flashes at 2 Hz

lit

RESTART: A PLC start–up is performed (transi-

tion from STOP to RUN). If the action is aborted,

a transition to STOP take place.

off

– lit

– off for 3 secs

– lit

General reset: General reset requested.

off

– lit

– flashes at 2Hz

for at least. 3

secs

– lit

General reset: General reset active

The NCK latency time group combines the following information:

S

NCK latency time

The foundation for the SINUMERIK 840Di Real–time property is the cyclic

activation of the NC system software at defined intervals.

Since the NC and Windows NT share the available processor resources of

the PLC, there can be delays (latency times) when calling the NCK. Latency

times greater than 200

µ

secs

are Real–time violations, for which the func-

tional integrity of the NC is not longer guaranteed.

The latency time display of the NCK can be used to continuously monitor

the latency behavior of the NCK over a period of 50 seconds. Following re-

placement of extension of the HW and/or SW components, it is thus pos-

sible to determine whether, and if so to what extent, these have an effect on

the real–time behavior of the NCK.

Note

For details of real–time properties of the SINUMERIK 840Di, refer to Subsec-

tion 1.1.4, Page 1-24.

Group: NCK

latency time

10 NC Start-Up with HMI Advanced