06.03

16.3 Travel to fixed stop with high-resolution torque reduction (SW 2.2 and higher)

16-512

Siemens AG, 2003. All rights reserved

SINUMERIK 840Di Manual (HBI) – 06.03 Edition

16.3.3

Setting parameters for SIMODRIVE drives

The requirements for an automatic or manual adjustment of the following SIMODRIVE drives:

–

SIMODRIVE 611 universal/universal E

–

SIMODRIVE POSMO CD/CA

–

SIMODRIVE POSMO SI.

are met with SW 4.1 and higher.

The following describes the function on the basis of a SIMODRIVE 611 universal (DP slave 611U)

drive. Please adapt your procedure for the other SIMODRIVE drives.

Note

If third-party drives are used, please read the manufacturer’s documentation to

see whether and how to set the parameters on the drive.

The resolution of the torque reduction is parameterized in the DP slave 611U in

parameter:

S

P0881 Torque reduction evaluation

As standard, in the DP slave parameter P0881 is scaled to: 16384.00

¢

1%

Examples for other resolutions:

–

1638.40

¢

0.1%

–

163.84

¢

0.01%.

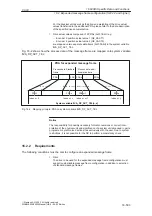

Setpoint torque T

set

of the drive is therefore calculated by:

T

set

= T

max

* ( 1 –

)

P0881 * TorRed[%]

16384 * 100%

T

max

:

Maximum possible drive torque from rated motor torque and parameter P1230 Torque limit value.

TorRed:

The percent specified via FXST for the reduced drive (control word in SIMODRIVE standard mes-

sage frame 102 to 107).

16.3.4

Setting parameters for the SINUMERIK 840Di NC

In the SINUMERIK 840Di NC system, the parameters for the resolution of the torque reduction are

set via the axis-specific machine data:

S

MD 37620: PROFIBUS_TORQUE_RED_RESOL (torque reduction resolu-

tion on PROFIBUS (LSB weighting)).

Parameter P0881

Scaling

Setpoint torque

T

set

16 840Di Specific Data and Functions