01.91

5 Configuring

5.13 FB 139 Data distributor

5.13

FB 139 DAT-VERT

Data distributor

Description

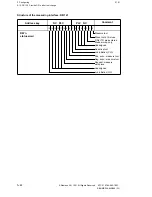

The function block "Data distributor" is used in conjunction with the computer link and code

carrier packages as well as for loading and unloading via tape. The FB is used for reading and

writing the active dynamic buffers.

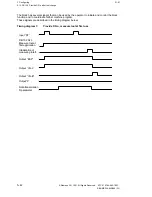

The FB "Data distributor" checks whether a job initiation is pending when a dynamic buffer is

occupied. If the job initiation is valid (i.e. no other job is running when the job is initiated), the

subroutine of the data distributor "UP: FB 139" is activated. The subroutine checks the para-

meters and determines the number of the subroutine where the processing of the required

command code is implemented. Before the relevant subroutine is called, an internal flag and

data word interface is assigned. There, the subroutine to be called reads the processing rule

and the internal statuses of the subroutine are stored in multi-cycle operation.

If a job is already being executed on initiation of a new job, the current job is aborted, any data

entered in accordance with the command code deleted and an error message entered into the

dynamic buffer.

If the "Job initiation" signal is not set in the next dynamic buffer to be processed, a check is

made whether the "Job running" signal is set. In this case, the subroutine to be processed is

called directly. At that time, the internal interfaces are defined and are continuously updated by

the subroutine called.

If an error occurs during processing of a job, the subroutine called reports back to the data

distributor; the latter then enters the error number in the dynamic buffer while setting the

"Error occurred" and "Job terminated" flags.

After the processing of a command code has been completed, the "Job executing" signal is

reset and the "Job terminated" signal set. For the command codes 0 to 4, the"Last cutting

edge reached" signal is also set when the last cutting edge is reached.

Note:

For all magazines other than turrets, the "Last cutting edge reached" signal is set for every

new cutting edge if the command code is 0. This is due to the fact that the number of cutting

edges cannot be specified via the setup data.

Loading with operator guidance

Loading with operator guidance is a special type of loading procedure. The essential difference

between this loading type and the standard loading procedure is that the data of the tool to be

loaded is written into the loading line of the magazine table. A tool is declared valid via

command code 10 (bit 8 "Tool not enabled" = 0) and an empty location searched for, which

is made available to the user at the interface for loading with operator guidance. While the user

positions this empty location at its loading position and inserts the required tool in the

magazine at this position, the data distributor remains in a wait state until the job is acknow-

ledged by the user via the interface. On negative acknowledgement, an error message is

entered into the active dynamic buffer and the operation terminated. In this case, the data in

the loading line is not deleted. On positive acknowledgement the operation is discontinued

immediately. This acknowledgement enables the user to transfer the tool data from the loading

line to the loading location by means of transfer block FB 128.

© Siemens AG 1991 All Rights Reserved 6FC5 197-0AA40-1BP1

5–45

SINUMERIK 840/880 (PJ)