5 Configuring

01.91

5.14 FB 155 Input via tape

5.14

FB 155 LOCHSTEG

Input via tape

Description

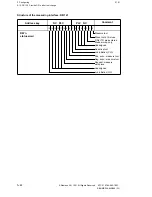

FB 155 loads the magazine with tool data via one of the main NC programs. The block gene-

rates its buffer DB (DB 135) in the initial setting and calculates the parameters.

In the initial setting, it also checks the initialized M function and enters the stop state (STS) if

any parameter is not valid; (accumulator 1: 0155, accumulator 2: 0030). Only M function num-

bers from "1 to 99" are valid. A check is made to find out whether the block has reserved

another dynamic buffer; if so, this buffer will be declared unassigned.

FB 155 is called unconditionally and constantly checks both the bit of the initialized M function

for "1" and the channel No., which was written into DW 3 by the NC cycle. After initiation, the

control word is preset and the R parameters read and written into the DB buffer (DB 135).

Then the data is converted and written into the DB buffer in the same manner as it has been

transmitted after the search for a free dynamic buffer in a single block transfer.

If all dynamic buffers are reserved, the request remains active until a free buffer is found; there

is no interrupt. Any subsequent, new initiation via the loading cycle is stored and initiates a

new processing cycle after the current job has been processed.

The dynamic buffer is only declared unassigned if no further job is pending. The data distribu-

tor is informed via the command code "Last cutting edge" that all tool data have been trans-

mitted.

At the first initiation, the user transfers the function number of the loading type "BELA" as flag

byte and the read disable as one bit. It should be ensured that the parameters entered by the

user are not used by FB 155 as scratch flags. Otherwise, the output parameters could be ex-

ceeded!

The user must route the read disable in line with FB 155. As long as the NC cycle has not

transferred the channel No. to the FB 155, the DB number of FB 155 is entered in the output

parameter as a pseudo DB (DB 135). The read disable is then constantly reset.

The FB 155 cooperates with the NC subroutine L 940, Loading cycle. The cycle L 940 reads

the PLC number (PLC MD) and NC channel number and transfers these data to the

corresponding PLC (DB 135, DW 3).

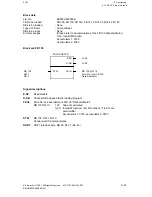

Response to NC stop

In the case of an NC stop, the NC program stops at the current block; FB 155 remains active

und waits for another M function. At the NC start, the NC program continues in the following

block and loading of the magazine is continued.

Response to "Reset"

The current tool is deleted from the magazine table in the case of a "Reset" of the NC to

avoid any incomplete entries in the magazine table; the dynamic buffer is declared unassigned

and is no longer ready.

Response to "Mode change"

The following modes correspond to an NC stop:

•

REPOS, INC FEED X, JOG

The following modes correspond to a reset:

•

MDI AUTOMATIC, PRESET, REFPOINT

5–56

© Siemens AG 1991 All Rights Reserved 6FC5 197-0AA40-1BP1

SINUMERIK 840/880 (PJ)