1 Brief Explanation

02.93

1.1 Tool management functions

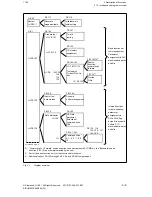

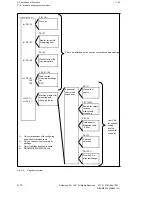

Selection, parameter assignment and linking of the function blocks (e.g. selection of direction)

with the machine program also depends on the machine configuration, including the selected

machine control strategy, and must therefore be carried out by the user.

The sequential controller used, for instance, for tool change and sorts must be generated by

the user in accordance with the machine configuration/mechanical characteristics and the se-

lected strategy.

The user is responsible for the application and adaptation of the present package to machine

configurations not covered by the package (see Section 3, Guidelines/Application criteria).

1.2

Requirements for tool management

The following requirements should be met by the tool management software:

•

Adaptable to a maximum number of machine configurations,

•

Short execution times of tool change procedures,

•

Arrangement of the tools in any sequence in the magazine/turret,

•

Fixed sequence of the tools when using turrets in certain turning machine configurations,

•

Availability of a maximum number of tools,

•

Use of tool management in controls that are integrated into a computer-controlled

manufacturing system,

•

Installation aids.

The tool management software for SINUMERIK 840/880 controls is able to meet all these

demands.

Shorter execution times and an arbitrary tool sequence are achieved because the time-

consuming search for the "old location" is no longer required for the tool change procedure

(tool-holding magazine/spindle) where tools are the same size (flexible location coding). This is

possible because the current magazine assignment is recorded in data blocks in the PLC

provided the machine configuration and selected control strategy permit this.

The volume of tool data which can be stored is restricted by the tool offset memory capacity,

16 Kbytes in the case of SINUMERIK 880, 32 Kbytes for SINUMERIK 840 (also referred to as

TO memory) and the current maximum length that can be used in the data blocks in the PLC,

that is 256 data words per submagazine.

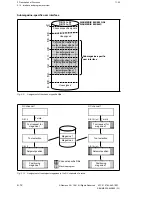

Integration into computer-controlled manufacturing systems is possible through the use of host

computers and/or code carriers for the input and output of tool data provided that the hardware

and software requirements for the computer link and connection of the code carrier have been

met (see Section 3, Guidelines).

Package 1, "Tool management for machines with active magazines/turrets", and, optionally,

package 2, "Functions for background magazines" are available for the machine-related

implementation of tool management in SINUMERIK 880 (for explanations of the terms used

see Section 2, General). For the hardware and software requirements of the control system

and other FB packages relevant to the tool management software refer to Section 3,

Guidelines.

Installation aids are currently available in the form of examples of operator interfaces and a

brief installation guide.

1–2

© Siemens AG 1991 All Rights Reserved 6FC5 197-0AA40-1BP1

SINUMERIK 840/880 (PJ)