2 Description of Functions

01.91

2.2.2 Loading

target location is occupied, disabled or reserved, the procedure is aborted and a fault message

issued.

Via the TO memory management, a free D number for each cutting edge of the tool is

searched for and stored in the reference list. The geometrical data are entered in the TO area.

In addition, P memories P 8 and P 9 (additional compensation) are defined for every block in a

transformation rule.

The source data for data transformation are taken from the adapter lists (data blocks of the

magazine table). If no adapter lists are available, the contents of the dynamic buffer (DW 70 to

DW 75) are entered in P 8 and P 9 of the relevant tool offset memory. Since the entry of data

in P 8 and P 9 is currently not supported by the computer link or code carrier, P 8 and P 9

have the value 0 if no adapter list is available.

During entry of the magazine data in the magazine table, the "replacement tool" and "location

occupied " bits are set in the identification DB = DB 152.

Reloading

For reloading, the ID and duplo numbers must be stored in the magazine table. The

"reloading" function is initiated by loading locator number 0 and command code 0. The

magazine is now searched for a tool that is assigned the same ID number and duplo number

as the tool whose data are stored in the dynamic buffer.

Loading with operator guidance via operator panel

The operator panel provides operator guidance during loading. The interface between operator

and tool management is established through DB 146, which is created during startup. Up to

software version 5, the following machine data are stored temporarily in data words DW 136 to

DW 138:

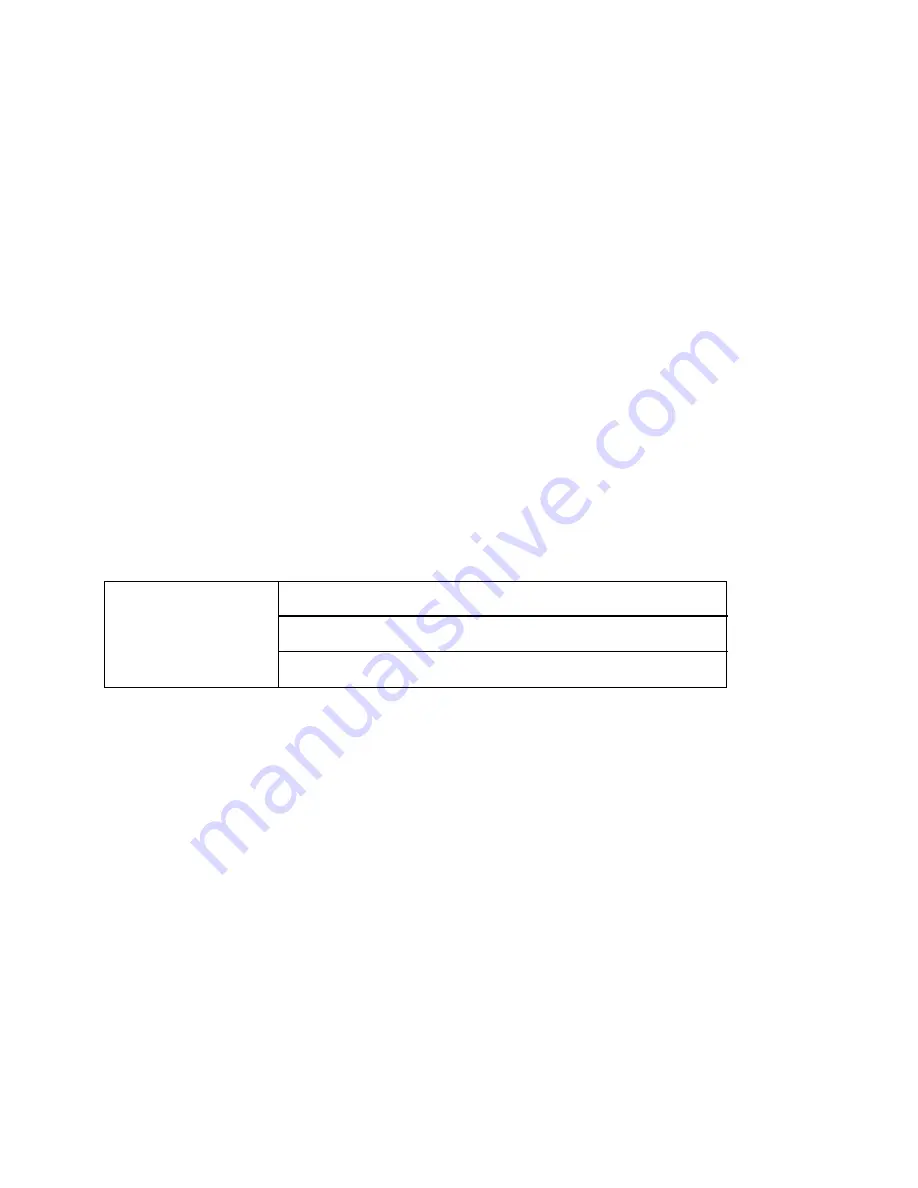

DB 146

DW 136

Magazine number of loading/unloading point

DW 137

Offset loading point 1

DW 138

Offset loading point 2

Magazine number of loading/unloading point

The number of the magazine containing the loading point is specified in this machine data.

With loading with operator guidance, the search for an empty location starts in this magazine.

If no empty location is found in this magazine, the search for an empty location is continued in

the chained magazines.

Offset loading point 1/2

The difference between actual position and loading point 1/2 is specified in this machine data.

Loading with operator guidance

If the user wishes to be prompted during loading, i.e. no locator number is specified, the

corresponding machine data must be set depending on the loading package used (computer

link m +11, bit 6; code carrier m +11, bit 5; tape m+11, bit 4 where m=7000 for PLC 1,

etc.).

2–22

© Siemens AG 1991 All Rights Reserved 6FC5 197-0AA40-1BP1

SINUMERIK 840/880 (PJ)