2.2

System configuration

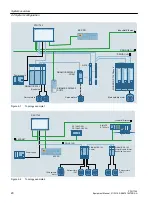

The SINUMERIK ONE combines CNC, HMI, PLC, closed-loop control and communication

tasks within a single PPU.

Components

For operation, programming, and visualization purposes, the corresponding operating software

is already integrated into the CNC software for the PPU and therefore runs on the high-

performance PPU module.

The following components can be connected to PPU:

● Distributed PLC I/O

– SIMATIC

e.g. ET200SP and ET200MP

● SINAMICS S120 drive system

● Feed motors, main spindle motors and direct-drive motors in synchronous and

asynchronous design:

– Servomotors: 1FT, 1FK

– Main spindle motors: 1PH, 1FE, 2SP1

– Direct-drive motors: 1FN3, 1FW6

● Handwheels

A maximum of three handwheels can be connected:

– Two handwheels via X143

– 1 using MCP and connection box.

● Increasing the number of axes

– NX10.3 / NX15.3

You can increase the number of axes connected to the NC using NX modules. Each

NX10.3 component can control up to 3 additional servo axes and each NX15.3

component can control up to 6 additional axes.

PROFINET

PROFINET I/O for PLC peripherals

x

PLC isochronous drives

x

PROFIsafe V2

x

Precondition: TIA Portal as of V15

System overview

2.2 System configuration

PPU 1740

Equipment Manual, 01/2019, A5E47615272B AA

19

Summary of Contents for SINUMERIK ONE PPU 1740 Series

Page 22: ...System overview 2 2 System configuration PPU 1740 22 Equipment Manual 01 2019 A5E47615272B AA ...

Page 82: ...Interface description 7 7 USB PPU 1740 82 Equipment Manual 01 2019 A5E47615272B AA ...

Page 92: ...Connectable components 8 1 NX10 3 NX15 3 PPU 1740 92 Equipment Manual 01 2019 A5E47615272B AA ...

Page 100: ...Spare parts and accessories PPU 1740 100 Equipment Manual 01 2019 A5E47615272B AA ...