1.5

Residual risks of power drive systems

When assessing the machine- or system-related risk in accordance with the respective local

regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must

take into account the following residual risks emanating from the control and drive components

of a drive system:

1. Unintentional movements of driven machine or system components during commissioning,

operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic

components

– External influences/damage

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open flames, as well as emissions of light, noise,

particles, gases, etc., can occur inside and outside the components under fault conditions

caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a risk

to people with a pacemaker, implants or metal replacement joints, etc., if they are too close

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

6. Influence of network-connected communication systems, e.g. ripple-control transmitters or

data communication via the network

For more information about the residual risks of the drive system components, see the relevant

sections in the technical user documentation.

Fundamental safety instructions

1.5 Residual risks of power drive systems

PPU 1740

Equipment Manual, 01/2019, A5E47615272B AA

15

Summary of Contents for SINUMERIK ONE PPU 1740 Series

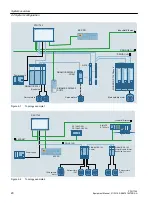

Page 22: ...System overview 2 2 System configuration PPU 1740 22 Equipment Manual 01 2019 A5E47615272B AA ...

Page 82: ...Interface description 7 7 USB PPU 1740 82 Equipment Manual 01 2019 A5E47615272B AA ...

Page 92: ...Connectable components 8 1 NX10 3 NX15 3 PPU 1740 92 Equipment Manual 01 2019 A5E47615272B AA ...

Page 100: ...Spare parts and accessories PPU 1740 100 Equipment Manual 01 2019 A5E47615272B AA ...