Project Planning Manual

SIPART DR20

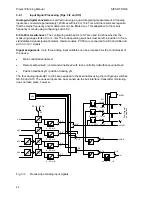

General, repeatedly encountered functions:

Manual setpoint input w

i

or setpoint ratio w

v

:

The setpoint wi can be adjusted using the

S

and

T

push buttons (12) in the controller types with a

facility for local setpoint adjustment providing the green LED next to the local/remote selector (13)

indicates "Iocal mode" and the green LED next to the display selector (8) indicates "Display of

setpoints". The adjustment is made every 0.1 s in steps with 0.01 %. The step size is increased

linearly with time so that larger ranges of adjustment can also be covered in a reasonable time. If

the adjustment is interrupted by releasing the pressed pushbutton, it can then be started again with

the smallest rate of adjustment. An adjustment over the complete measuring range lasts approx.

7 s.

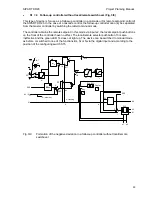

x-tracking:

It is possible to provide x-tracking for all types of controllers using configuring switch S17 = 1. This

means that the setpoint is made equal to the actual value and the setpoint ratio to the actual ratio

and tracked as soon as, and also as long as, the control loop is isolated in the output of the device

by manual, tracking, DDC backup mode or by y-blocking or a safety manipulated variable

(identified by /A = no automatic mode in the function displays). Thus when returning to automatic

mode, the control loop can be closed without bumps and drift with xd = 0. The setpoint may have

changed in the process.

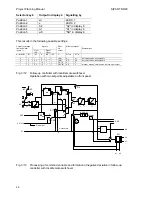

Setpoint limit and setpoint ramp:

In all controller types the setpoint or the setpoint ratio can be limited by the parameters wa and we

within the measuring range adjusted. In the ratio controller and ratio station, the range of

adjustment of the ratio factor is defined by these parameters (page 38).

The rate of change can be adjusted using the parameter Tw (tS). The time Tw refers to a change

in setpoint over the complete measuring range. The setpoint ramp is always effective except with

x-tracking.

The setpoint ramp can be adjusted between 1 and 9984 s, but only between 1 and 100 s in the

ratio controller and ratio station (S1 = 7 and 8).

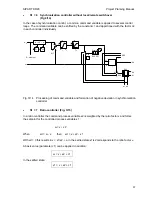

Formation of negative deviation:

The negative deviation is calculated from the effective setpoint w and the effective actual value x:

xd = w - x

and is the negation of the deviation x

w

. Further processing is described in Section 3.2.3 (page 43).

Alarm monitor:

This can be used to monitor the minimum and/or maximum values of a variable.

The variable to be monitored is selected using configuring switch S22, the type of monitoring is

selected using configuring switch S23. Configuring switch S24 defines whether the alarms are to

be set only in the parameterization level or also in the operation level of the device.

26