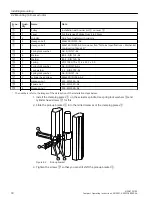

Connecting

5

5.1

Basic safety notes

WARNING

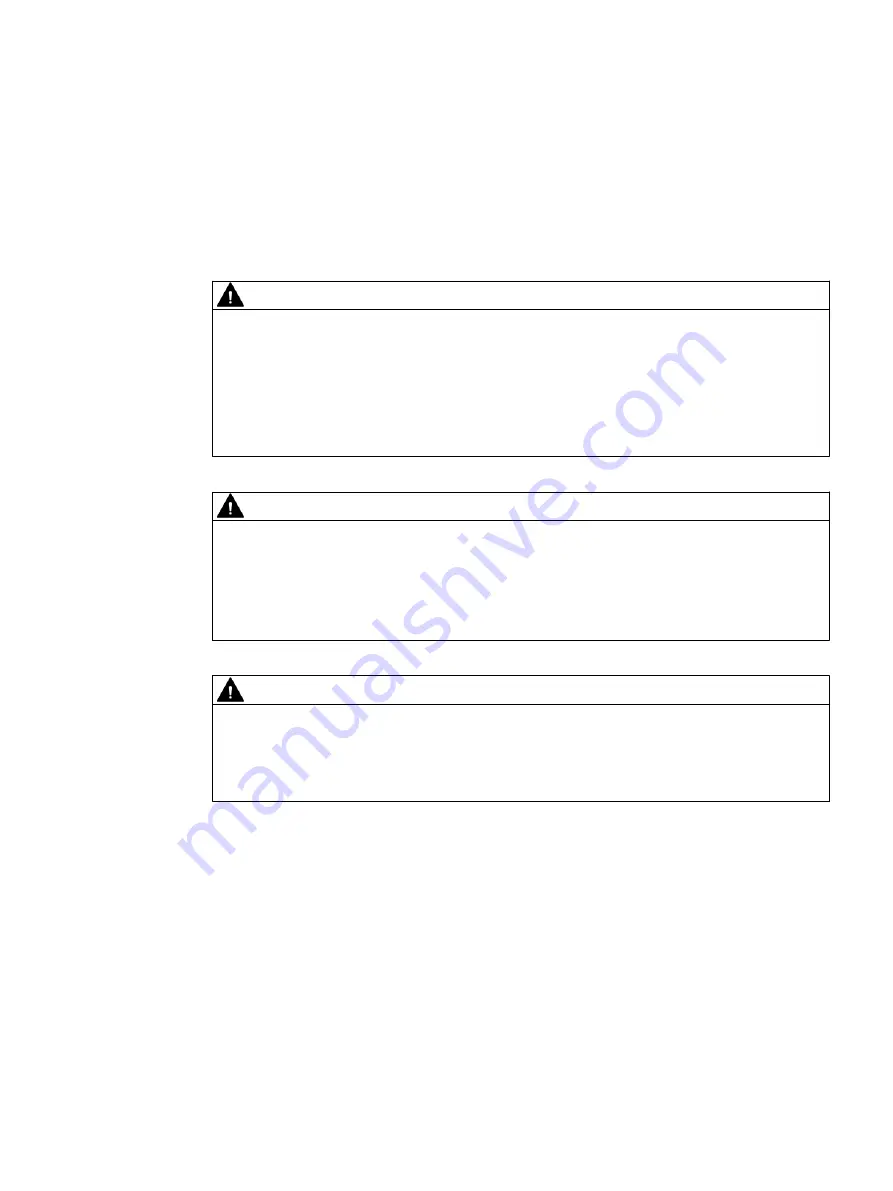

Lever for position detection

Danger of crushing and shearing with mounting kits which use a lever for position detection.

During commissioning and ongoing operation, severing or squeezing of limbs could occur as

a result of the lever. Risk of injury when working on control valves due to the high operating

force of the pneumatic actuator.

• Do not reach into the range of motion of the lever following mounting of the positioner and

mounting kit.

WARNING

With intrinsically device version (Ex i)

Risk of explosion in hazardous areas.

For intrinsically safe device versions only the certified circuits may be connected as auxiliary

power supply, control and signal circuits.

• Make sure that the power source of the used circuits is marked as intrinsically safe.

WARNING

Eliminating or reducing the sources of ignition within the equipment

Potential fire hazard.

• The product must be connected to an energy-limited circuit.

• Connect the device according to the information in Input (Page 43).

SIPART PS100

Compact Operating Instructions, 05/2021, A5E50188940-AA

25