Alarm, fault and system messages

12.2 Diagnostics

SIPART PS2 with PROFIBUS communication

Operating Instructions, 09/2007, A5E00127926-07

225

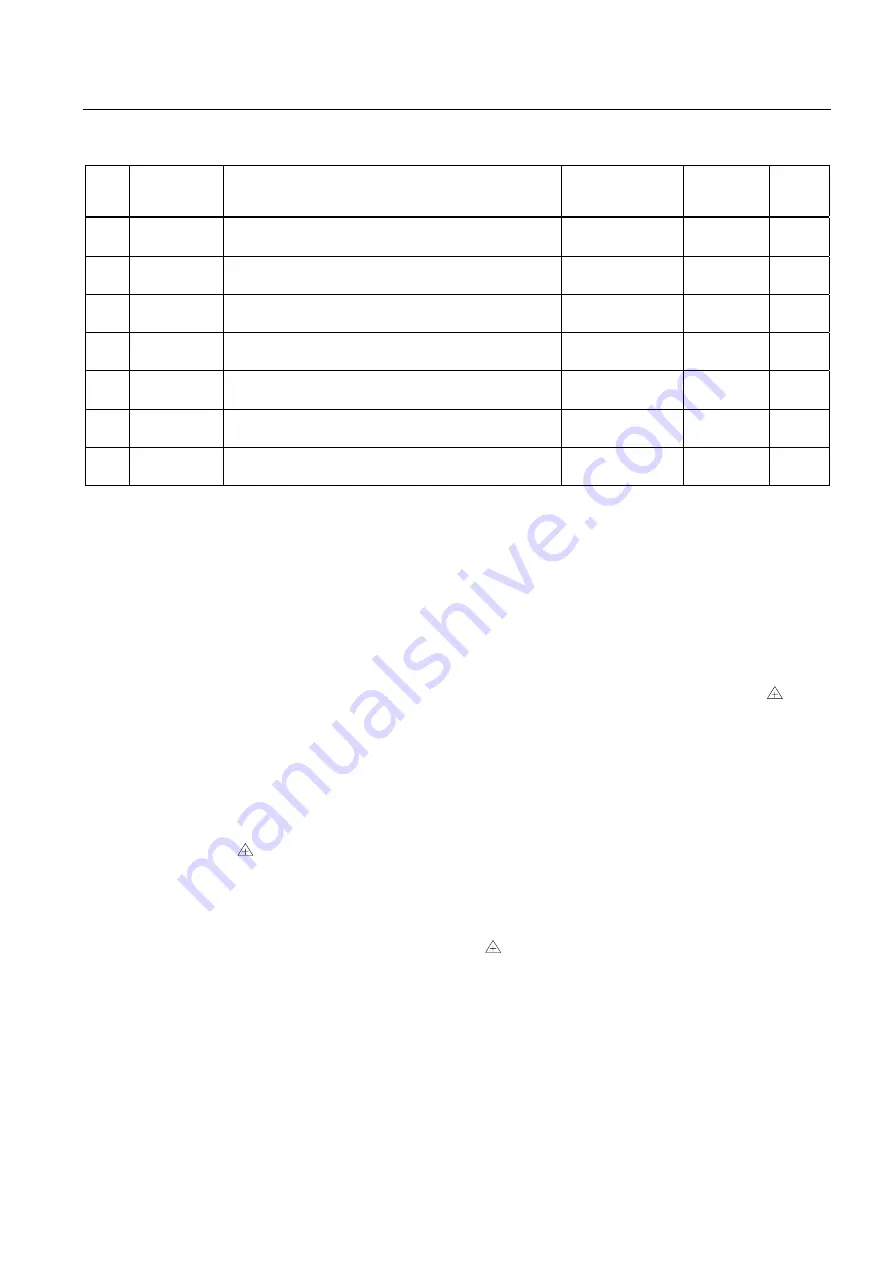

No.

Abbreviation Meaning

Values that can

be displayed

Unit

Reset

possibl

e

46

WT05

Number of operating hours in the actuating range

WT05

0 ... 4.29E9

Hours

X

47

WT10

Number of operating hours in the actuating range

WT10

0 ... 4.29E9

Hours

X

48

WT30

Number of operating hours in the actuating range

WT30

0 ... 4.29E9

Hours

X

49

WT50

Number of operating hours in the actuating range

WT50

0 ... 4.29E9

Hours

X

50

WT70

Number of operating hours in the actuating range

WT70

0 ... 4.29E9

Hours

X

51

WT90

Number of operating hours in the actuating range

WT90

0 ... 4.29E9

Hours

X

52

WT95

Number of operating hours in the actuating range

WT95

0 ... 4.29E9

Hours

X

12.2.3

Meaning of diagnostics values

1 STRKS - stroke number

The movements of the actuator in operation are summed up and can be read here as the

stroke number. Unit: 100% strokes, i.e. the path between 0 and 100 % and back. The value

is written in a non-volatile memory every 15 minutes. It can be set to zero using the

increment button.

2 CHDIR - number of changes of direction

Every change of direction of the actuator caused in the dead zone is noted in the closed-loop

controller and added to the number of changes of direction.

The value is written in a non-volatile memory every 15 minutes. It can be set to zero using

the increment button.

3 CNT - number of fault messages

Every fault is noted in the closed-loop controller and added to the number of fault messages.

The counter can be set to zero using the increment button.

4 A1CNT - number of alarms 1

and