SIPLUS HCS3200

Operating Instructions, 07/2014, A5E31278506C/002

45

Communication

9

9.1

Cyclic data transfer

Communication between the DP master and heating controller is performed exclusively via

cyclic data.

You can access the cyclic data in the PLC software via the inputs (message data) and the

outputs (control data).

9.2

Cyclic input data

The cyclic input data can be addressed in the S7 through the process image or I/O

commands.

Process image inputs (PII)

The process image for the inputs PII contains the status information for the individual

modules. All addresses are specified as an offset relative to the base address 0.0. The

actual addresses are obtained from the configuration of the overall system.

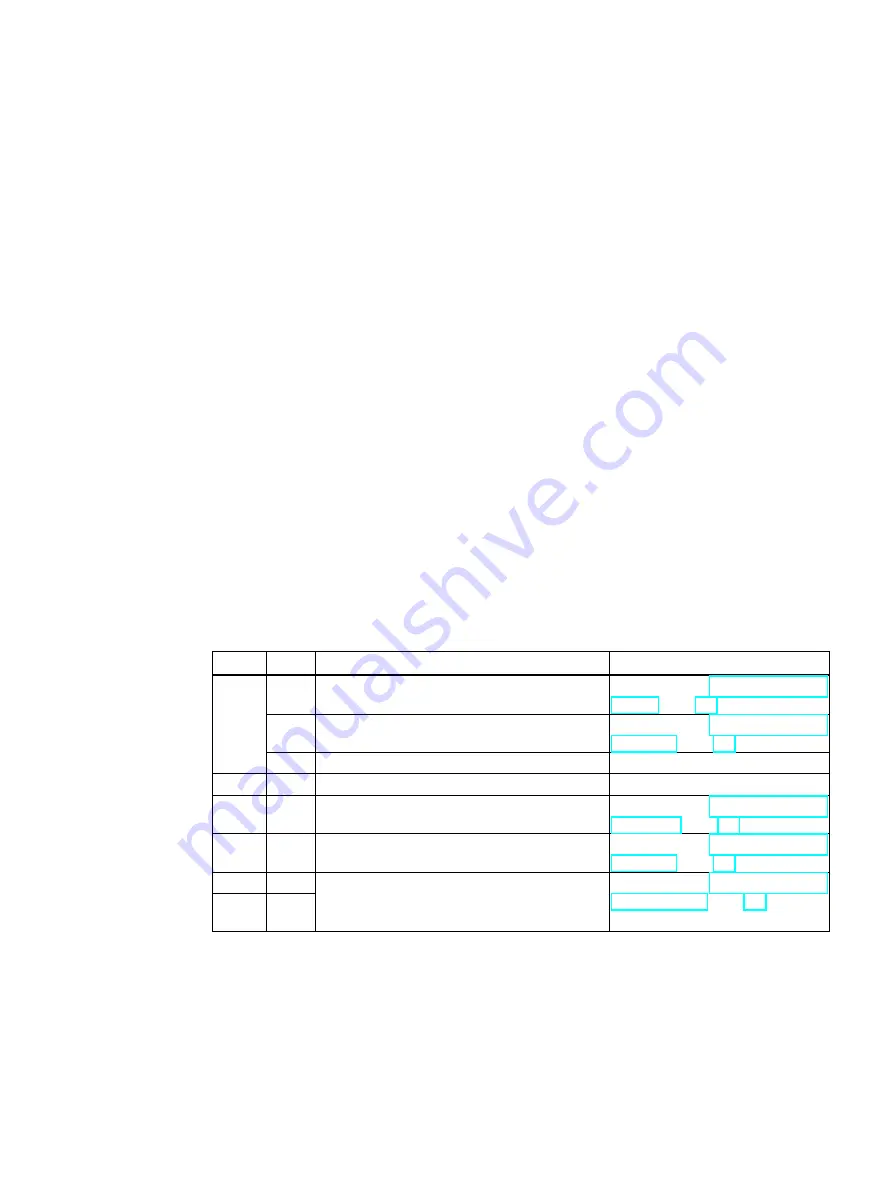

Table 9- 1

Addressing of inputs

Byte

Bit

Meaning

Description

0

0

= 0: Heating switched off

= 1: Heating switched on

Refer to section Power output

1

= 0: Line voltage compensation is not active

= 1: Line voltage compensation is active

Refer to section Line voltage com-

2 ... 7 0 (reserved)

1

0 (reserved)

2

Temperature measurement in °C

Refer to section Temperature

monitoring (Page 43)

3

Factor for line voltage compensation in %

Refer to section Line voltage com-

4

Voltage measured value Lxy

Refer to section Line supply volt-

age monitoring (Page 41)

5

Summary of Contents for SIPLUS HCS3200

Page 1: ......

Page 2: ......

Page 24: ...Mounting 5 3 Final work SIPLUS HCS3200 24 Operating Instructions 07 2014 A5E31278506C 002 ...

Page 74: ......