The thermal differential equation in Section

2.9.2 Overload Protection Using a Thermal Replica

one term that considers the ambient temperature

ϑ

U

. For this the “cold” state with

ϑ

U

= 40 °C or 104 °F is

assumed (temperature without heating itself). This temperature difference is scaled to the maximum admis-

sible temperature and then designated with Θ

U

. The thermal differential equation is

[ueberlastschutz-differentialgl, 1, en_GB]

Otherwise the function is the same, as in Section

2.9.2 Overload Protection Using a Thermal Replica

. To create

the relation between current and temperature, the device needs the temperature at rated current of the

protected object.

In the event of failure of the temperature input via the thermobox, the device works with an accepted temper-

ature of 40 °C or 104 °F. The result shows the same conditions as with the thermal protection without ambient

temperature (Section

2.9.2 Overload Protection Using a Thermal Replica

Hot-Spot Calculation and Determination of the Ageing Rate

The overload calculation according to IEC 60354 calculates two quantities relevant for the protection function:

the relative ageing and the hot-spot temperature in the protected object. The user can install up to 12 temper-

ature measuring points in the protected object. Via one or two RTD boxes and a serial data connection the

measuring points inform the overload protection of the 7UT6x about the local coolant temperature. One of

these points is selected to form the relevant point for hot-spot calculation. This point should be situated at the

insulation of the upper inner turn of the winding since this is the location of the hottest temperature.

The relative ageing is acquired cyclically and summed up to a total ageing sum.

Cooling Methods

The hot-spot calculation is dependent on the cooling method. Air cooling is always available. Two different

methods are distinguished:

•

AN (Air Natural): natural air circulation and

•

AF (Air Forced): forced air circulation (by means of ventilation)..

If extra liquid coolants are available, the following types of coolants can be used:

•

ON

(Oil Natural = naturally circulating oil): Because of emerging differences in temperature the coolant

(oil) moves within the tank. The cooling effect is not very intense due to its natural convection. This

cooling variant, however, is almost noiseless.

•

OF

(Oil Forced = forced oil circulation): An oil pump makes the coolant (oil) move within the tank. The

cooling effect of this method is therefore more intense than with the ON method.

•

OD

(Oil Directed = forced-directed oil circulation): The coolant (oil) is directed through the tank. Therefore

the oil flow is intensified for sections which are extremely temperature-intensive. Therefore, the cooling

effect is very good. This method has the lowest temperature rise.

Hot-Spot Calculation

The hot-spot temperature of the protected object is an important status value. The hottest spot relevant for

the life-time of the transformer is usually situated at the insulation of the upper inner turn. Generally the

temperature of the coolant increases from the bottom upwards. The cooling method, however, affects the

rate of the temperature drop.

The hot-spot temperature consists of two parts:

•

the temperature at the hottest spot of the coolant (included via RTD-box),

•

the temperature rise of the winding turn caused by the transformer load.

RTD box 7XV5662-xAD can be used to acquire the temperature of the hottest spot. It captures the tempera-

ture value and transmits these to the respective interface of device 7UT6x. The RTD box 7XV5662-xAD is able

2.9.4

Functions

2.9 Thermal Overload Protection

SIPROTEC 4, 7UT6x, Manual

203

C53000-G1176-C230-5, Edition 09.2016

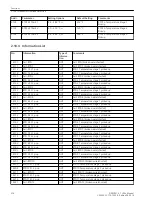

Summary of Contents for SIPROTEC 4 7UT6 Series

Page 394: ...394 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Page 482: ...482 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Page 504: ...504 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Page 522: ...522 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Page 528: ...528 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Page 538: ...538 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Page 664: ...664 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Page 666: ...666 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...

Page 684: ...684 SIPROTEC 4 7UT6x Manual C53000 G1176 C230 5 Edition 09 2016 ...