Although the heat distribution on the rotor bars may severely differ during motor starting, the different

maximum temperatures in the the rotor are not pertinant for motor restart inhibit (see

). It is much

more important to establish a thermal replica, after a complete motor start, that is appropriate for the protec-

tion of the motor's thermal condition.

shows, as an example, the heating processes during

repeated motor starts (three starts from cold operating condition), as well as the thermal replica in the protec-

tion relay.

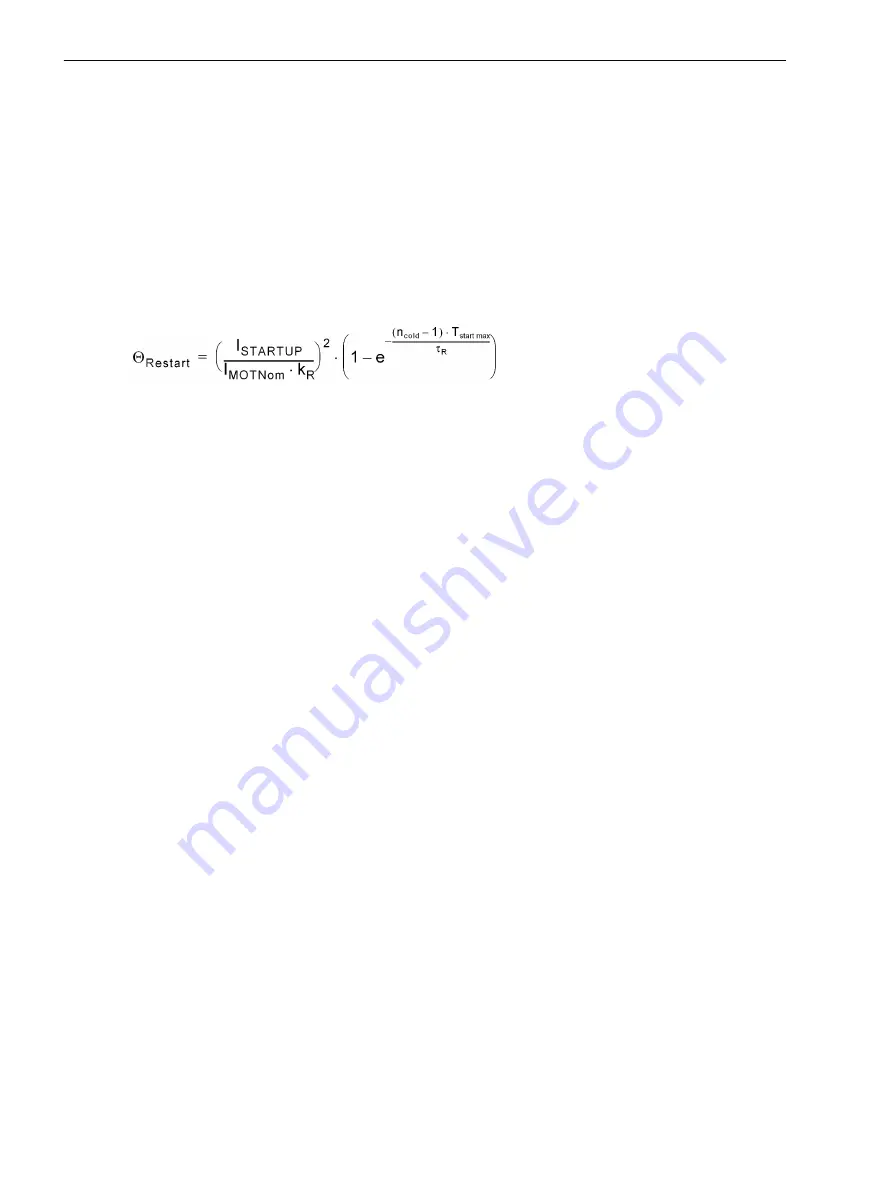

Restart Threshold

If the rotor temperature has exceeded the restart threshold, the motor cannot be restarted. The blocking

signal is not lifted unless the rotor temperature has fallen below the restarting limit, that is, when exactly one

start becomes possible without exceeding the excessive rotor temperature limit. Based on the specified motor

parameters the device calculates the normalized restarting limit Θ

Restart

:

[formel-wiedereinschaltgrenze-121103-he, 1, en_US]

Where:

Θ

Restart

=

Temperature threshold below which restarting is possible

k

R

=

k-factor for the rotor, calculated internally

Ι

STARTUP

=

Startup current

Ι

MOTNom

=

Nominal motor current

T

start max

=

Maximum startup time

τ

R

=

Thermal time constant of the rotor, calculated internally

n

cold

=

Permissible number of startups in cold condition

The restarting limit Θ

Restart

is displayed as operational measured value in the ”thermal measured values”.

Rotor Overload Detection

If the rotor temperature exceeds 100% of the maximum temperature calculated from the thermal rotor profile,

there is a risk of motor damage. If this threshold value is exceeded, either tripping occurs or an overload

message is issued. The desired reaction can be determined via parameter 4311

ROTOR OVERLOAD

. If param-

eter is set to

OFF

, rotor overload will not be detected.

Restart Time

The motor manufacturer allows a maximum number of cold (n

cold

) and warm (n

warm

) startup attempts. There-

after, another startup is not permitted. A certain time must have passed — restarting time T

Restart

— to ensure

that the rotor has cooled off (operational measured value 661).

Equilibrium Time

This thermal behavior is provided for in the protection as follows: Each time the motor is shut down, the timer

starts (address 4304

T Equal

). It takes into account the different thermal conditions of the motor parts at the

moment of shutdown. During the equilibrium time, the thermal replica of the rotor is not updated. It is main-

tained constant to replicate the equilization process in the rotor. Then, the thermal replica with the corre-

sponding time constant (rotor time constant x extension factor) cools down. During the equilibrium time the

motor cannot be restarted. As soon as the temperature sinks below the restarting limit, the next restart

attempt can be made.

Minimum Inhibit Time

Regardless of thermal replicas, some motor manufacturers require a minimum inhibit time after the maximum

number of permissible startup attempts has been exceeded.

Functions

2.8 Motor Protection

150

SIPROTEC 4, 7SJ62/64, Manual

C53000-G1140-C207-8, Edition 08.2016

Summary of Contents for SIPROTEC 4

Page 8: ...8 SIPROTEC 4 7SJ62 64 Manual C53000 G1140 C207 8 Edition 08 2016 ...

Page 18: ...18 SIPROTEC 4 7SJ62 64 Manual C53000 G1140 C207 8 Edition 08 2016 ...

Page 30: ...30 SIPROTEC 4 7SJ62 64 Manual C53000 G1140 C207 8 Edition 08 2016 ...

Page 540: ...540 SIPROTEC 4 7SJ62 64 Manual C53000 G1140 C207 8 Edition 08 2016 ...

Page 594: ...594 SIPROTEC 4 7SJ62 64 Manual C53000 G1140 C207 8 Edition 08 2016 ...

Page 720: ...720 SIPROTEC 4 7SJ62 64 Manual C53000 G1140 C207 8 Edition 08 2016 ...