Functions

6-106

7SJ63 Manual

C53000-G1140-C120-1

6.10

Start Inhibit for Motors (66/68)

General

The rotor temperature of a motor generally remains well below its maximum allowable

temperature during normal operation and even during severe loading conditions. How-

ever, during motor starting, the rotor can heat up quickly. If multiple starting attempts

are made in a short duration of time, the rotor could suffer thermal damage. Therefore,

the 7SJ63 motor start blocking feature is available. A motor start blocking signal is ini-

tiated when the relay projects rotor temperature will exceed the maximum allowable

rotor temperature, and blocking continues until the calculated rotor temperature de-

creases below the reset level. To block starting, the blocking signal must be connected

to a binary output whose contact is inserted in the motor starting circuit.

6.10.1 Description of Start Inhibit for Motors

Determining

Excessive Rotor

Temperature

Because the rotor current cannot be measured directly, the stator current must be

used to generate a thermal profile of the rotor. The excessive rotor temperature is cal-

culated using the highest of the three phase currents. The thermal limit values for the

rotor winding are based on manufacturer’s data regarding the nominal starting current,

maximum permissible starting time, and the number of starts permitted from cold and

warm conditions. From this data, the device performs the necessary calculations to

establish the thermal rotor profile and issues a blocking signal until the thermal rotor

profile decreases below the restarting limit.

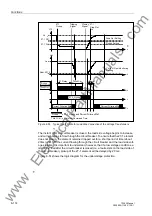

Although the heat distribution at the rotor brushes can range widely during motor start-

ing, the different maximum temperatures in the rotor do not necessarily affect motor

start blocking (see Figure 6-46). It is much more important to establish a thermal pro-

file, after a complete motor start, that is appropriate for the protection of the motor’s

thermal condition. Figure 6-46 shows, as an example, the heating processes during

repeated motor starts (three starts from cold operating condition), as well as the ther-

mal reproduction by the protective relay.

Figure 6-46

Temperature Curve at the Rotor and the Thermal Profile during Repeated Start-

ing Attempt

Restarting Limit

If the rotor temperature has exceeded the restarting limit, the motor cannot be restart-

ed. When the rotor temperature goes below the restarting limit, that is, when exactly

Θ

L

Maximum Allowable Rotor Temperature

Temperature Curve @:

Rotor Cage Bar Upper Side Limit

Rotor Cage Bar Lower Side Limit

Thermal

Profile

Restarting

Motor Started

1st Start

Motor Started

2nd Start

Motor Started

3rd Start

t

Rotor Tempe-

rature Equilib-

rium Time

Rotor Tempe-

rature Equilib-

rium Time

Rotor Tempe-

rature Equilib-

rium Time

www

. ElectricalPartManuals

. com