Typical circuits

A.2 Typical circuits for safety-related shutdown

SIRIUS 3RM1 motor starter

Manual, 06/2016, A5E0345285095020A/RS-AE/005

185

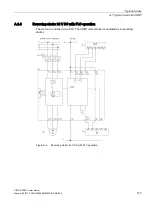

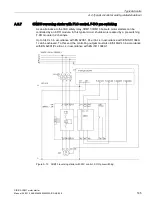

A.2.7

3RM13 reversing starter with PLC control, F-DO pm-switching

As an alternative to the 3SK safety relay, 3RM11/3RM13 Failsafe motor starters can be

controlled by an F-DO module. In this typical circuit, shutdown is realized by a pm-switching

F-DO module in 2 channels.

Up to SILCL 3 in accordance with EN 62061, PL e/Cat. 4 in accordance with EN ISO 13849-

1 can be achieved. To this end, the controlling outputs must also fulfill SILCL3 in accordance

with EN 62061/PL e/Cat. 4 in accordance with EN ISO 13849-1.

Figure A-10 3RM13 reversing starter with PLC control, F-DO pm-switching