Example circuits

A.3 Special applications

SIRIUS 3RW50 soft starter

Manual, 09/2019, A5E35628455002A/RS-AA/001

219

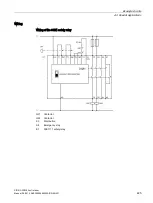

A.3.3

EMERGENCY STOP shutdown to SIL 1 or PL c with a 3SK1 safety relay

The 3RW50 soft starter has no effect or influence on the safety function of the application.

For this reason, it is neither positively nor negatively considered in the safety application, and

also does not have to be included in the calculation for proof according to the standards.

If achievement of SILCL 1 according to IEC 62061:2005 or PL c according to

EN ISO 13849-1:2015 is required, the series connection of an additional contactor with the

3RW50 soft starter, in conjunction with a suitable safety relay (e.g.: 3SK1111), is required,

as well as monitoring of the contactor's auxiliary contacts.

Basic configuration

①

Emergency stop

②

3RT20 contactor

③

3RW50 soft starter

④

Motor

⑤

3SK1 safety relay