68

PBD-51041066

SITRANS LG270 - Operating Instructions

44295-EN-140321

•

Constant level

•

Filling

•

Emptying

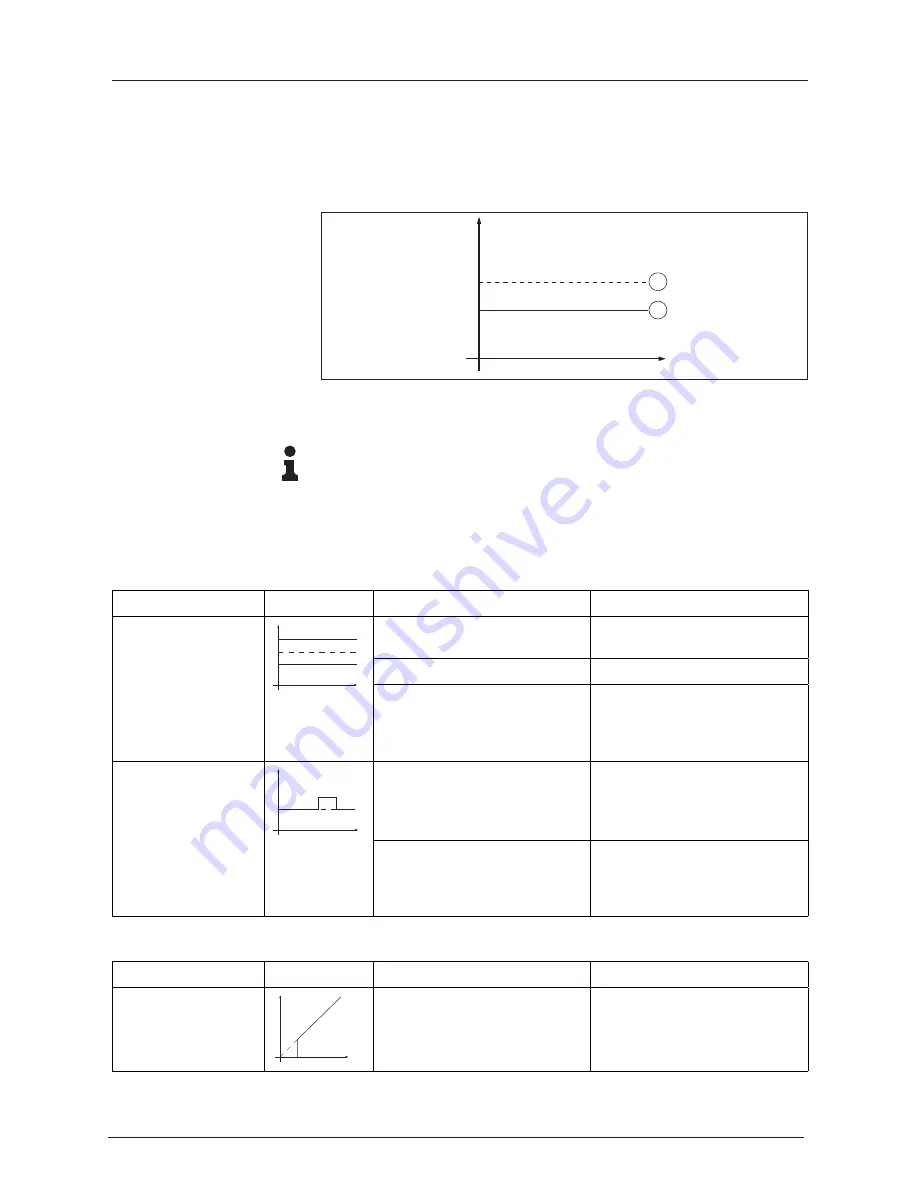

The images in column "

Error pattern

" show the real level with a bro-

ken line and the level displayed by the sensor as a continuous line.

1

2

Level

time

0

Fig. 31: The broken line 1 shows the real level, the continuous line 2 shows the

level displayed by the sensor

Note:

•

Wherever the sensor displays a constant value, the reason could

also be the fault setting of the current output to "

Hold value

"

•

In case of a too low level indication, the reason could be a line

resistance that is too high

Measurement error with constant level

Fault description

Error pattern

Cause

Rectification

1. Measured value

shows a too low or too

high level

Level

time

0

– Min./max. adjustment not

correct

– Adapt min./max. adjustment

–

Wrong linearization curve

–

Adapt linearization curve

–

Running time error (small

measurement error close to

100 %/serious error close to

0 %)

– Repeat setup

2. Measured value

jumps towards 100 %

Level

time

0

– Due to the process, the ampli-

tude of the product echo sinks

– A false signal suppression was

not carried out

– Carry out a false signal sup-

pression

– Amplitude or position of a

false signal has changed (e.g.

buildup); false signal suppres

-

sion no longer matches

– Determine the reason for the

changed false signals, carry out

false signal suppression, e.g.

with buildup

Measurement error during filling

Fault description

Error pattern

Cause

Rectification

3. Measured value re-

mains in the area of the

bottom during filling

Level

time

0

– Echo from the probe end larger

than the product echo, for

example, with products with

ε

r

< 2.5 oil-based, solvents, etc.

– Check parameter "Medium"

and "Vessel height", adapt if

necessary