Configuration

6.1 Basic knowledge for configuring

SIVACON 8PS - Configuring with LX system

Configuration Manual, 10/2011, A5E02194899-02

89

6.1.3.2

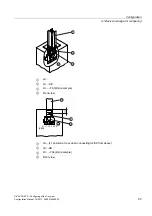

Universal busbar connection units with T tap-off unit

Application area

LX universal connection units with T tap-off unit are used as infeed units when direct tap-off

upwards is necessary due to lack of space. Connection to the LX system can be carried out

via any trunking unit listed in the catalogue and any junction unit.

Design

The universal connection unit (AS) with T tap-off unit is delivered with the following

components:

●

With connection tags fixed according to customer requirements

●

With a connection positioned in the centre of the connection unit for every trunking unit

and every junction unit (without joint block).

Phase sequence and tag distances

The relevant perspective is decisive for configuring the phase sequence and tag distances:

●

Edgewise installation position of the busbars in the unit

●

Direction of view of the end of the connection unit busbar with PEN(N) on right and T tap-

off plug upwards.

●

In addition, the same assignments apply for phase sequence and tag distances as for the

connection unit without T tap-off unit.

+LX-1.

+LX-2.

①

Direction of view

②

T tap-off plug

③

PEN(N) position