SIWAREX WP231

Manual, 07/2014, A5E31238908A-02

179

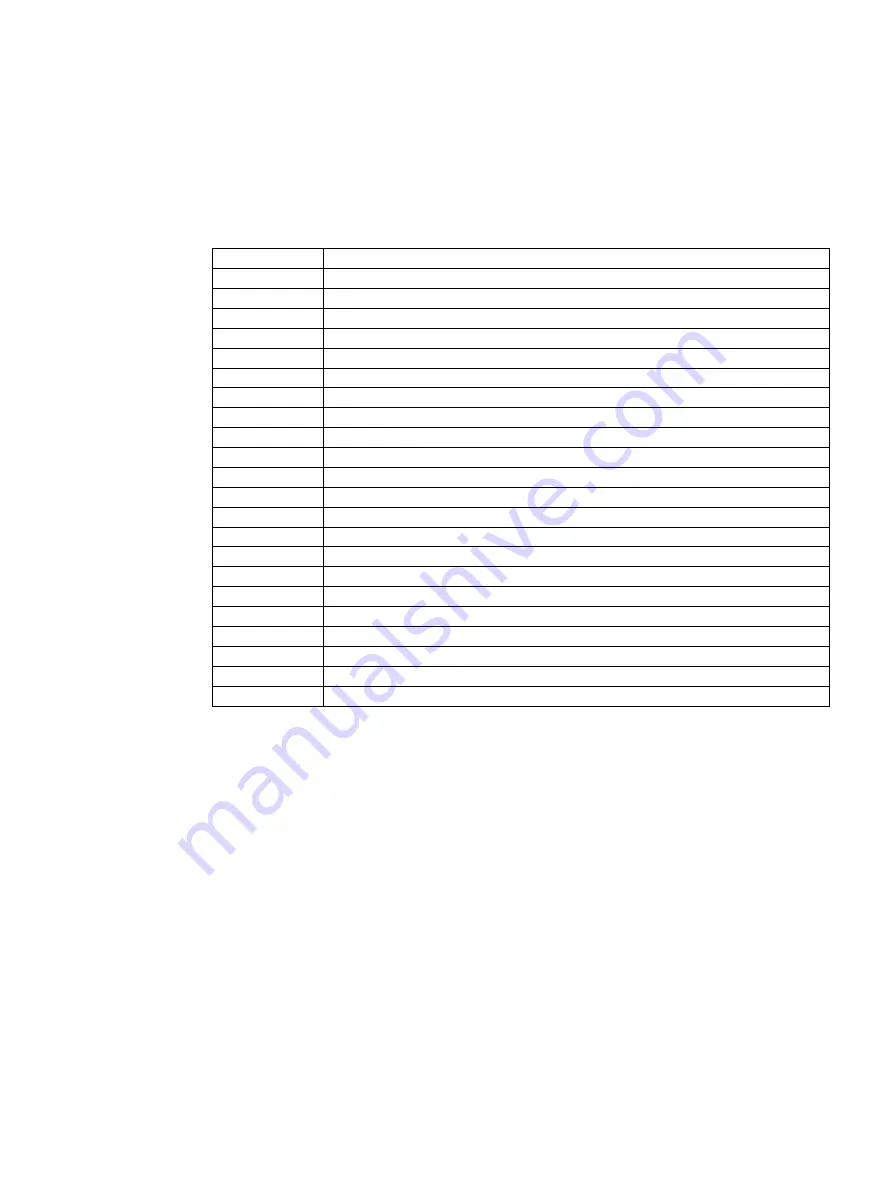

List of abbreviations

B

ASCII

American Standard Code for Information Interchange

B

Gross weight

CPU

Central processor, in this case SIMATIC CPU

DB

Data block

FB

SIMATIC S7 function block

HMI

Human machine interface (e.g. SIMATIC Operator Panel)

HW

Hardware

NAWI

Non-automatic weighing instrument

NAW

Non-automatic scales

OIML

Organisation Internationale de Metrologie Legale

OP

Operator Panel (SIMATIC)

PC

Personal computer

pT

Preset tare (predefined tare weight with manual taring)

RAM

Random access memory

PLC

Programmable logic controller

STEP 7

Programming device software for SIMATIC S7

T

Tare weight

TM

Technology module

TP

Touch Panel (SIMATIC)

UDT

Universal Data Type (S7)

WRP

Write protection

LC

Load cell(s)

NR

Numerical range

Summary of Contents for SIWAREX WP231

Page 16: ...Safety notes 2 1 General safety instructions SIWAREX WP231 16 Manual 07 2014 A5E31238908A 02 ...

Page 132: ......

Page 174: ...Technical data 13 3 Approvals SIWAREX WP231 174 Manual 07 2014 A5E31238908A 02 ...

Page 180: ...List of abbreviations SIWAREX WP231 180 Manual 07 2014 A5E31238908A 02 ...

Page 182: ...Index SIWAREX WP231 182 Manual 07 2014 A5E31238908A 02 ...