Document Number: 129-369

Installation Instructions

September 30, 2002

Installation

If you are mounting an actuator on a new valve, begin

with the instructions in Figure 3.

Removing the Actuator

from the Valve

1. Remove the actuator cover.

2. Disconnect the wires and conduit, if installed.

3. Loosen the valve stem retainer using a 5 mm hex

wrench and lower the valve stem into the valve.

4. Loosen the yoke nuts in the actuator yoke using a

5 mm hex wrench.

5. Remove the actuator from the valve, use care not

to damage the valve stem.

Continue with

Mounting an Actuator to a Valve

.

EA0134R1

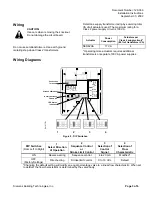

Figure 3. Preparing a new Valve.

Mounting an Actuator to a Valve.

NOTE:

Install the packing heating element,

(P/N 599-00417), if used, before proceeding.

EA0380R1

5 mm

≈

3x360

°

≈

5 x 360

°

«MAN

«MAN «

Figure 4.

NOTE:

Make sure the yoke nuts are loose enough to

allow the actuator to slip over the bonnet.

See Figure 5.

EA0382R1

4

3

Figure 5.

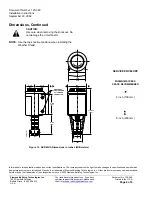

EA0384R1

5 mm

5

Figure 6.

NOTE:

Hold the stem retainer in place as you tighten

it around the valve stem. See Figure 6.

EA0383R2

5 mm

MAX. TORQUE

40 lb-in (4.5 Nm)

6

6

1

Figure 7.

NOTE:

Position the actuator to accommodate the

wiring. Hold the actuator in place while

tightening the yoke nuts. See Figure 7.

EA0381R1

>3x360

°

«AUTO «

2

7

Page 2 of 6

Siemens Building Technologies, Inc.

Figure 8.