Document No. 997-1002

Installation Instructions

February 12, 2009

Page 4 of 8

SLX Series

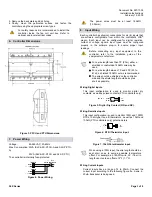

Figure 8: Current Input – 2-Wire Transducer.

Connect the current input according to the following figure if

a 3-wire, 4-20mA transducer is being used.

Figure 9: Current Input – 3-Wire Transducer.

Connect the current input according to the following figure if

the transducer is powered by its own power source.

Figure 10: Current Input – Transducer with its Own

Power Source.

Wiring Voltage Inputs

Voltage inputs have a range of 0 to 10VDC. Connect the

voltage input according to the following figure if a 3-wire 0-

10V transducer is being used.

Figure 11: Voltage Input – 3-Wire Transducer.

Connect the voltage input according to the following figure if

the transducer is powered by its own power source.

Figure 12: Voltage Input – Transducer with its Own

Power Source.

On the SLX-ASC-PFCU-A and SLX-P-PTU-A, the

onboard 24VAC output with a DC power supply can

be used to supply the current loop, as shown in

Figure 9. It can also be used to supply the voltage,

as shown in Figure 11

.

Refer to the transducer

installation guide for further details.

9. SLX-RTS/SLX-STAT

Wiring

Each controller is compatible with the SLX-RTS line of

standard room sensors. Refer to the SLX-RTS and SLX-STAT

installation instructions for wiring details.

10. Output Wiring

The SLX-ASC-PFCU and SLX-P-PTU controllers have

physical connections for four (4) relay contact outputs and four

(4) triac outputs. In addition to these outputs, the SLX-ASC-

PFCU-A and SLX-P-PTU-A controllers have two (2) universal

outputs. All of these outputs are software configurable.

Before connecting any input equipment to the

controller, refer to the installation guide of the

equipment manufacturer.

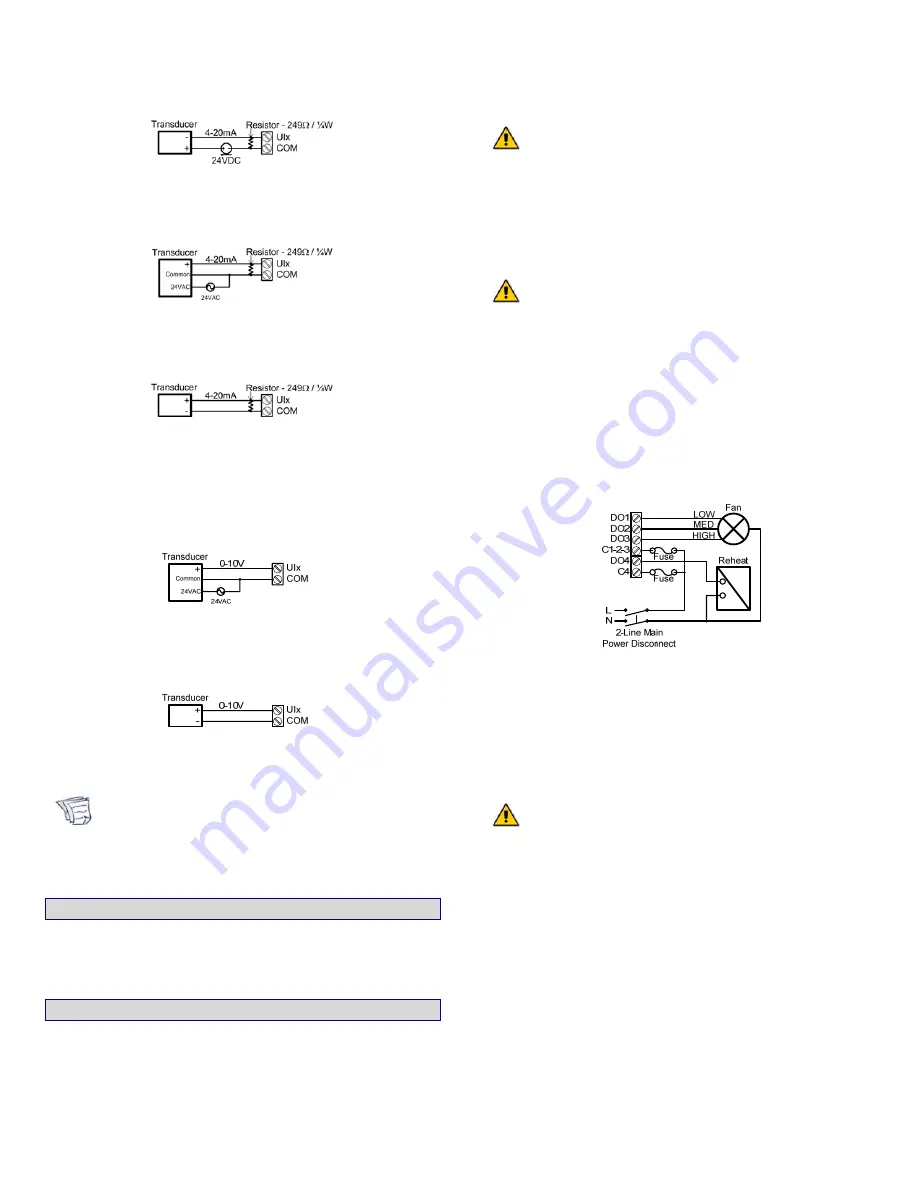

Wiring Relay Contact Outputs

Three (3) relay contact outputs (DO1-DO3) can switch 3A

(inductive/resistive) for fan speed control up to 277VAC, and

one (1) relay contact output (DO4) can switch 3A (inductive)

and 10A (resistive) for heater control up to 277VAC.

•

Relay contact output cables must remain

between 18 and 14AWG. Select the proper

gauge according to the current load.

•

All digital relay contact outputs on PFCU and

PTU controllers are normally open.

•

There is no voltage present on the digital output

terminals, so an external power supply should

be used if necessary.

•

It is recommended to use a 4A fast-acting, high-

breaking fuse to protect the relay contact outputs

(DO1-3) and a 15A fast-acting, high-breaking

fuse to protect the relay contact output (DO4)

against short circuiting when high voltage is

being used.

Figure 13: Relay Contact Output – Fan and Reheat

Powered by External 85-265VAC Power Supply.

Wiring Triac Outputs

The four (4) triac outputs can switch 1A at 20.4-265VAC and

can be used to turn equipment and devices on and off (two-

state outputs) and to control valve and damper actuators

using stroke time or Pulse Width Modulation (PWM).

•

Triac output cables should be between 20 and

18AWG. They must be at least 18AWG if they

are switching high voltage.

•

To measure the state of a triac output, an

external load must be connected.

•

When high voltage is used, you must use a 4A

fast-acting, high-breaking fuse to protect the

triac outputs against short circuiting.

•

It is not necessary to use a fuse when the

onboard 24VAC output is being used with the

triac outputs since it already has built-in short

circuit protection.

•

The triac outputs work in pairs (DO5-DO6 and

DO7-DO8) and cannot work with two different

voltages. For example, the DO5-DO6 switch

high voltage (85-265VAC) and DO7-DO8 switch

the onboard 24VAC.