7PG2113/4/5/6 Solkor Description of Operation

6.6

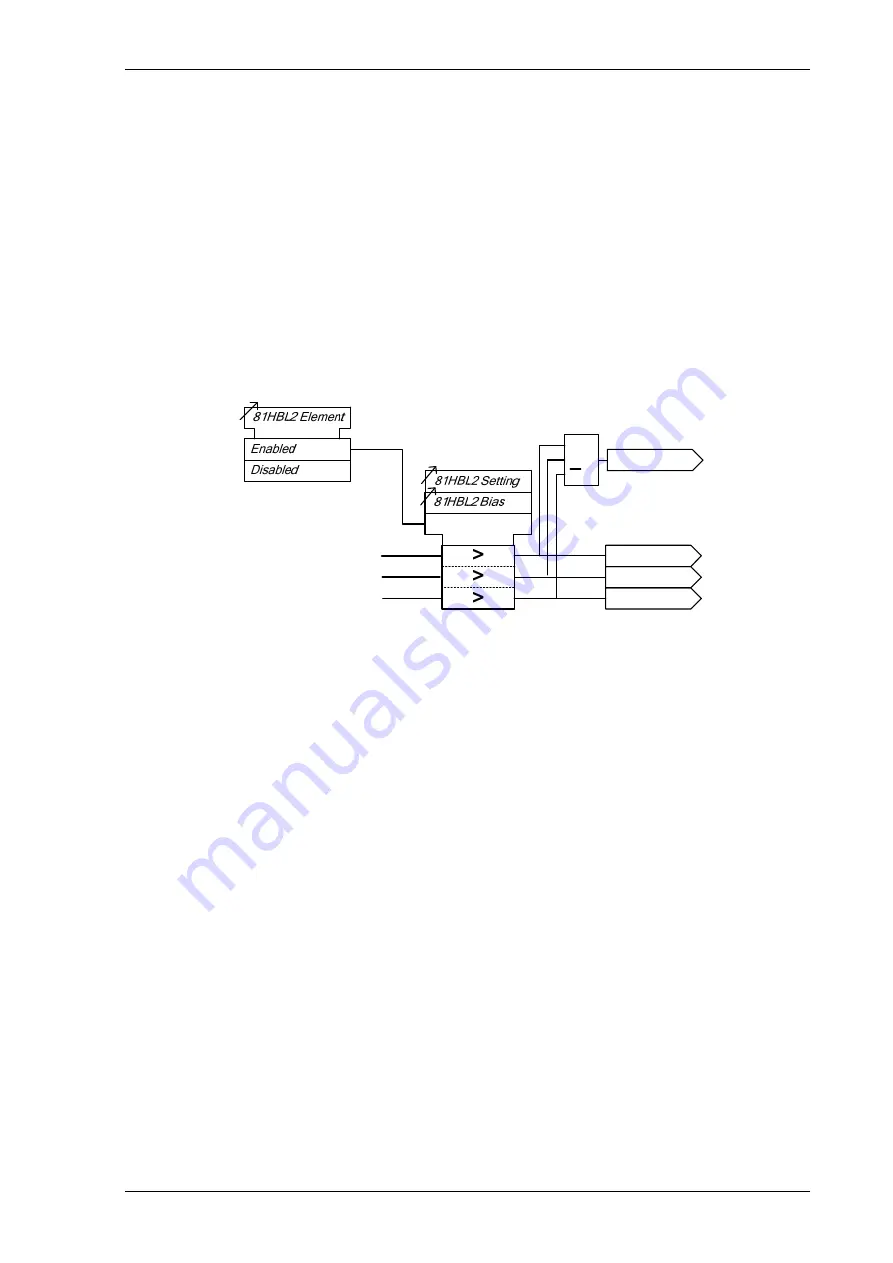

2nd Harmonic Block/Inrush Restraint (81HBL2) phase

elements only

Inrush restraint detector elements are provided, these monitor the line currents.

The inrush restraint detector can be used to block the operation of selected elements during transformer

magnetising inrush conditions.

The

81HBL2 Bias

setting allows the user to select between

Phase

,

Sum

and

Cross

methods of measurement:

Phase

Each phase is inhibited separately.

Sum

With this method the square root of the sum of the squares of the second harmonic in each

phase is compared to each operate current individually.

Cross

All phases are inhibited when any phase detects an inrush condition.

An output is given where the measured value of the second harmonic component is above the

81HBL2

setting.

IL1

IL2

IL3

L2 81HBL2

c

L1 81HBL2

L3 81HBL2

81HBL2

> 1

Figure 6.6-1 Functional Diagram for Harmonic Block Feature (81HBL2)

6.7

Demand

Maximum, minimum and mean values of line currents, voltages and power (where applicable) are available as

instruments which can be read in the relay INSTRUMENTS MENU or via Reydisp.

The

Gn Demand Log Time Sync

when set as

ENABLED

configures the Demand Log Update Period (see

below) equal to the

DATA STORAGE > Data Log Period

setting.

The

Gn Demand Log Update Period

setting is used to define the time/duration after which the instrument is

updated. The updated value indicates the maximum, minimum and mean values for the defined period. Note that

this setting can be over-ridden by the

Gn Demand Log Time Sync

setting.

The

Gn Demand Window

setting defines the maximum period of time over which the demand values are valid. A

new set of demand values is established after expiry of the set time.

The

Gn Demand Window Type

can be set to

FIXED

or

PEAK

or

ROLLING

.

When set to

FIXED

the maximum, minimum and mean values demand statistics are calculated over

fixed Window duration. At the end of each window the internal statistics

are reset and a new window is started.

When set to

PEAK

the maximum and minimum values since the feature was reset are recorded.

When set to

ROLLING

the maximum, minimum and mean values demand statistics are calculated over

a moving Window duration. The internal statistics

are updated when the window advances every

Updated Period

.

The statistics can be reset from a binary input or communication command, after a reset the update period and

window are immediately restarted.

©2010 Siemens Protection Devices Limited Chapter 1 Page 76 of 80