Back tamper switch installation

The back tamper switch (Fig.1 item 26) is required

for SSF Larmklass 2 and EN Alarm Grade 3.

The back tamper switch is delivered with SPCP333

or is available as an optional extra (SPCY130).

Mounting the wall fixing plate

¾

Mount the SPC enclosure in the appropriate

position on the wall using all three fixings (see

Fig. 8 item 1).

¾

Draw a line around the inside of the back

tamper cutout (see Fig. 8 item 2) to provide a

guide for the wall plate on the fixing wall.

¾

Remove the enclosure from the wall.

¾

Place the wall plate (Fig 9, item 1) on the wall

centring it precisely around the rectangle

previously drawn (Fig. 9, item 2).

¾

Ensure all four flanges on the wall plate are

flush with the wall.

¾

Mark the four fixings on the wall plate.

¾

Drill and use suitable screws (max. 4 mm) for

the wall substrate.

¾

Fit the wall plate to the wall.

Fitting the back tamper switch

¾

Insert the tamper switch (Fig. 10 item 2) into

the back of the enclosure so that the plunger

faces outwards. (Fig. 10 item 1)

¾

Fit the enclosure back onto the wall using the

three fixings previously removed.

¾

Visually check to ensure there is a flush finish

between the wall plate and the enclosure

metalwork.

WARNING:

If the wall fixing plate is not accurately aligned then

the enclosure will not sit properly on its fixings.

Wiring the back tamper switch

¾

Connect one end of the tamper leads to

terminal block CN4 (Fig.1 item 25).

¾

Plug the two connectors at the other ends of

the leads onto the COM (common) and NO

(normally open) spade connectors on the back

tamper switch.

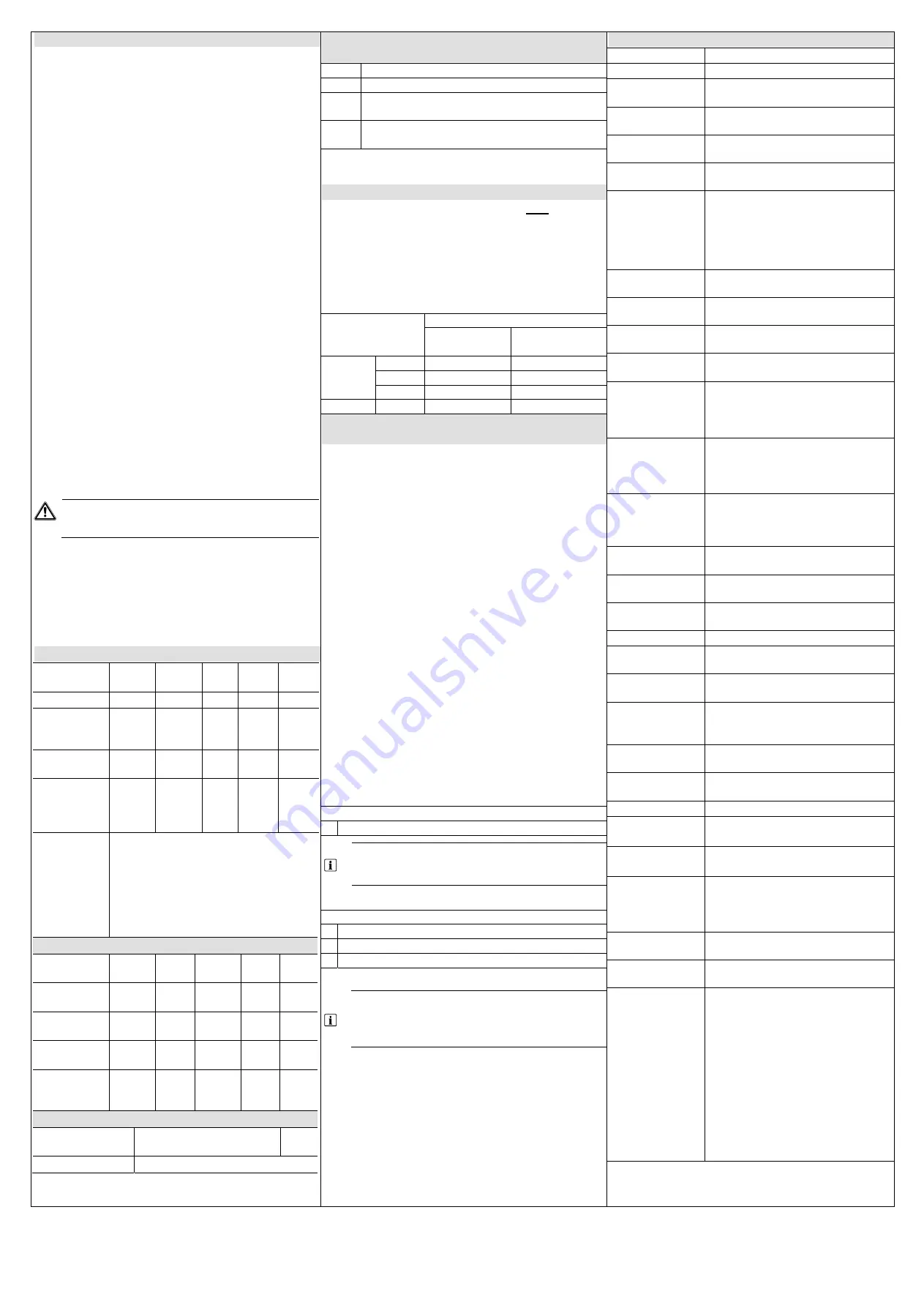

Appendix A: LED Status

Condition

Mains

green

Battery

green

Fuse

red

Limit

*

red

Status

green

Normal On

On

Off

Off

On

Mains OK,

battery

charging

On Flash

On

Mains fail,

battery OK

Off On On

Mains OK,

and battery

not installed

or faulty.

On Off On

Mains fail,

and battery

not installed,

faulty or in

deep

discharge

protection

mode.

All LEDs off

Output 1 fuse

open

Single

Flash

On

Output 2 fuse

open

Double

Flash

On

Expander

fuse open

Triple

Flash

On

More than

one fuse open

On

On

Current

exceeded on

any output

On

On

PSU switcher

failure

Off Flash

Battery link missing

All LEDs flash together

* Current limit

Appendix B: Battery link position (Fig. 1,

item 8)

Link

Description

DTX

Do not use.

17 Ah

Select this option if a 17Ah battery is fitted to

the PSU

7 Ah

Select this option if a 7Ah battery is fitted to

the PSU.

Note:

Only one of the above links can be fitted to

this header.

A

ppendix C: Choosing the stand-by battery

The table below shows the maximum total current

(in mA) that can be drawn from all outputs for EN

compliance. Note that other limits apply, for

example, the maximum current that can be drawn

from each of outputs 1 and 2 is 750 mA.

Available current in mA =

1000 * (0.85 * battery capacity in Ah) / (standby

time in hours) - 77 mA

Battery Capacity

7 Ah

(Grade 2)

17 Ah

(Grade 3)

Standby

Time

(hours)

12

419 1127

24

171 525

30

121 405

60

Not to be used

164

Appendix D: Fitting additional expanders in

the SPC hinged enclosure

The enclosure can accommodate:

•

1 x Battery (17 Ah max.)

•

1 x PSU Expander (SPCP330)

•

3 x I/O Expanders (optional)

To access the expanders and the PSU, open the

front lid to view the hinged mounting bracket. The

boards are secured to the hinged mounting bracket

by four mounting pillars.

To access or install a PSU in this enclosure:

¾

With an appropriate screwdriver, loosen (but do

not remove) the top two securing screws on the

mounting bracket.

¾

Gently push the mounting bracket in an upward

direction until the screws are free from contact

with the bracket.

¾

Slowly but firmly pull the mounting bracket out

until it rotates down and is secured by the

resting pins

¾

The underside of the mounting bracket and the

enclosure provides space for additional

expanders to be installed (secured by four

mounting pillars).

The PSU is secured to the front of the enclosure by

mounting pillars.

See Fig. 6: Mounted PSU

1

Battery

Please ensure that battery flaps are used to

hold the battery securely when mounted in

the cabinet.

See Fig. 7: Rotated views

1

Battery

2

Expanders

3

SPC controller or PSU

When installing the SPCP330 (PSU and

Expander), ensure that the 4-pin cable is

securely attached to the connector on the

expander and to the PSU beneath.

Technical data

Power supply

Type A (EN50131-1)

Mains voltage

230 V AC, +10 to -15 %, 50 Hz

Mains fuse

500 mA T (replacable part on mains

terminal block)

Power

consumption

Max. 220 mA at 230 V AC

Operating

Current

Max. 117 mA at 12 V DC (all relays

activated)

Quiescent

Current

Max. 77 mA at 12 V DC

Output Voltage

11-14 V DC in normal conditions

(mains powered and fully charged

battery), min. 9.5 V DC when powered

by secondary device (before system

shut down to battery deep discharge

protection)

Low voltage

trigger

7.5 V DC

Over voltage

protection

15 V DC

Peak to Peak

ripple

Max. 5% of output voltage

Auxiliary power

(nominal)

Max. 1500 mA at 12 V DC (750 mA

per output)

Battery type

SPCP332: YUASA NP7-12FR (7 Ah)

SPCP333: YUASA NP17-12FR

(17 Ah)

(battery not supplied with product)

Battery charger

SPCP332: 72h for 80 % of battery

capacity

SPCP333: 24h for 80 % of battery

capacity

Battery

protection

Current limited to 2 A (fuse protected),

deep discharge protection at 10.5 V

DC +/- 3 % (fault at deep discharge

v 0.5 V DC)

Number of on-

board zones

8

EOL resistor

Dual 4K7 (default), other resistor

combinations configurable

Number of on-

board relays

2 (single-pole changeover, 30 V DC /

max. 1 A resistive switching current)

Field bus

X-BUS on RS-485 (307 kb/s)

Calibration

No calibration checks required

(calibrated at manufacturing)

Serviceable

parts

No serviceable parts available

Tamper contact

SPCP332: Front spring tamper, back

tamper

SPCP333: Front spring tamper

Operating

temperature

0 to +40 °C

Relative

humidity

Max. 90 % (non-condensing)

Colour

RAL 9003 (signal white)

Dimensions

(W x H x D)

SPCP332: 264 x 357 x 81 mm

SPCP333: 326 x 415 x 114 mm

Weight

SPCP332: 4.7 kg

SPCP333: 6.3 kg

Housing

SPCP332: Small metal housing (>1.2

mm mild steel)

SPCP333: Hinged metal housing

(>1.2 mm mild steel)

Housing can

contain up to

SPCP333: 3 additional expanders

(size 150 x 82 mm)

Environmental

Class

Class II Indoor General

Standards

SPCP332

Certified according:

EN50131-1:2006 (Grade 2, Class II

Indoor General),

TS50131-3:2003 (Grade 2),

EN50131-6:2008 (Grade 2),

SSF 1014 ed.3:2005 (Larmklass 1)

SPCP333

EN50131-1:2006 (Grade 3, Class II

Indoor General),

TS50131-3:2003 (Grade 3),

EN50131-6:2008 (Grade 3),

SSF 1014 ed.3:2005 (Larmklass 2)