2/8

Siemens Building Technologies

CC1N7814en

HVAC Products

31.10.2002

Warning notes

To avoid injury to persons, damage to property or the environment, the following

warning notes should be observed!

Do not open, interfere with or modify the actuators!

·

Ensure protection against electric shock hazard by providing adequate protection

for the connection terminals

·

Check to ensure that wiring is in an orderly state and that the wires are firmly con-

nected

Mounting notes

·

Ensure that the relevant national safety regulations are complied with

·

The connection between actuator drive shaft and controlling element must be

rigid

with

no mechanical play

Possible connection with drive shaft or hub:

·

Groove with Woodruff key

·

Drive shaft with flat edge and matching counterpiece

To avoid inadmissible loads on bearings caused by rigid hubs, it is recommended to

use compensating clutches with no mechanical play (e.g. metal bellows clutches).

Only the specified cable may be used (refer to Basic Documentation P7550). The ca-

ble’s shielding must be connected to the printed circuit board using the tab provided.

Ensure that the actuator’s housing is connected to functional earth (FE) of the system.

If necessary, remove isolating layers of paint from the fixing points on the burner’s

casing or run separate earth wires.

For detailed information, refer to «Installation Inctructions for the LMV5x system»

J7550.1.

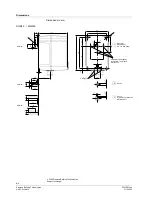

CAN bus

AGG5.6...

SQM4...

FE

Basic un

it

LMV5...

7814z

03

e/

0502

The working range is given on the type field and must be observed when mounting the

actuator. To ensure the actuator is accurately located on the burner, a positioning pin of

6 mm diameter must be fitted on the mounting surface.

Positive connection

Cable and cable

shielding

Working range of

actuator