4/8

Siemens Building Technologies

CC1N7814en

HVAC Products

31.10.2002

Standards

Conformity to EEC directives

- Electromagnetic compatibility EMC (immunity)

89 / 336 EEC

- Low-voltage directive

73 / 23 EEC

Service notes

·

Maintenance work must be carried out by qualified staff

·

Each time an actuator has been replaced, check to ensure that wiring is in an or-

derly state and that the wires are firmly connected

When replacing an actuator, the following points must be checked and, if necessary,

corrected:

·

Addressing

(assignment

of

functions)

·

Bus

termination

·

Adjustment of the curvepoints of electronic fuel / air ratio control (e.g. with the

LMV51...)

Disposal notes

The actuator contains electrical and electronic components and may not be disposed of

together with household waste.

Local and currently valid legislation must be observed.

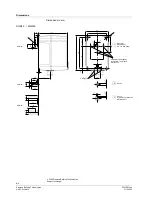

Mechanical design

The housing is made of die-cast aluminium.

The cover is made of impact-proof and heat-resistant plastic.

Color of cover: Black

Stepper motor

In connection with the basic unit (e.g. LMV51...): Via the display and operating unit

AZL5X (refer to Basic Documentation P7550).

RAST3.5 terminals (supplied together with the AGG5.720 / AGG5.721).

SQM45...: Spur gears made of plastic with small backlash and permanent lubrication.

SQM48...: Spur gears made of steel with small backlash and permanent lubrication.

Made of black-finished steel, ready fitted to the front of the geartrain (SQM48... uses a

drive shaft made of hardened steel).

The front of the geartrain is used as the mounting surface. The actuator has 4 fixing

holes and 1 elongated hole for the positioning pin.

Alternatively, the actuator can be secured from the side of the controlling element with

3 self-tapping screws.

Replacement

Housing

Actuator

Adjustment of switching

points / position

indication

Electrical connections

Geartrain

Drive shaft

Mounting and fixing