74/238

Building Technologies

Modular Heating Controller RMH760B

CE1P3133en

HVAC Products

6 Boiler temperature control

05.02.2007

b

50

48

52

°C

44

46

t

t

reset

TBo

TBoSetpt

31

32

D0

9

TBuOffPt

TBuOnPt

b Reset

integral

TBo

Actual value of the boiler temperature

TBoSetpt

Boiler temperature setpoint

t

Time

TBuOffPt

Burner’s switch-off temperature

t

reset

Time to reset

TBuOnPt

Burner’s switch-on temperature

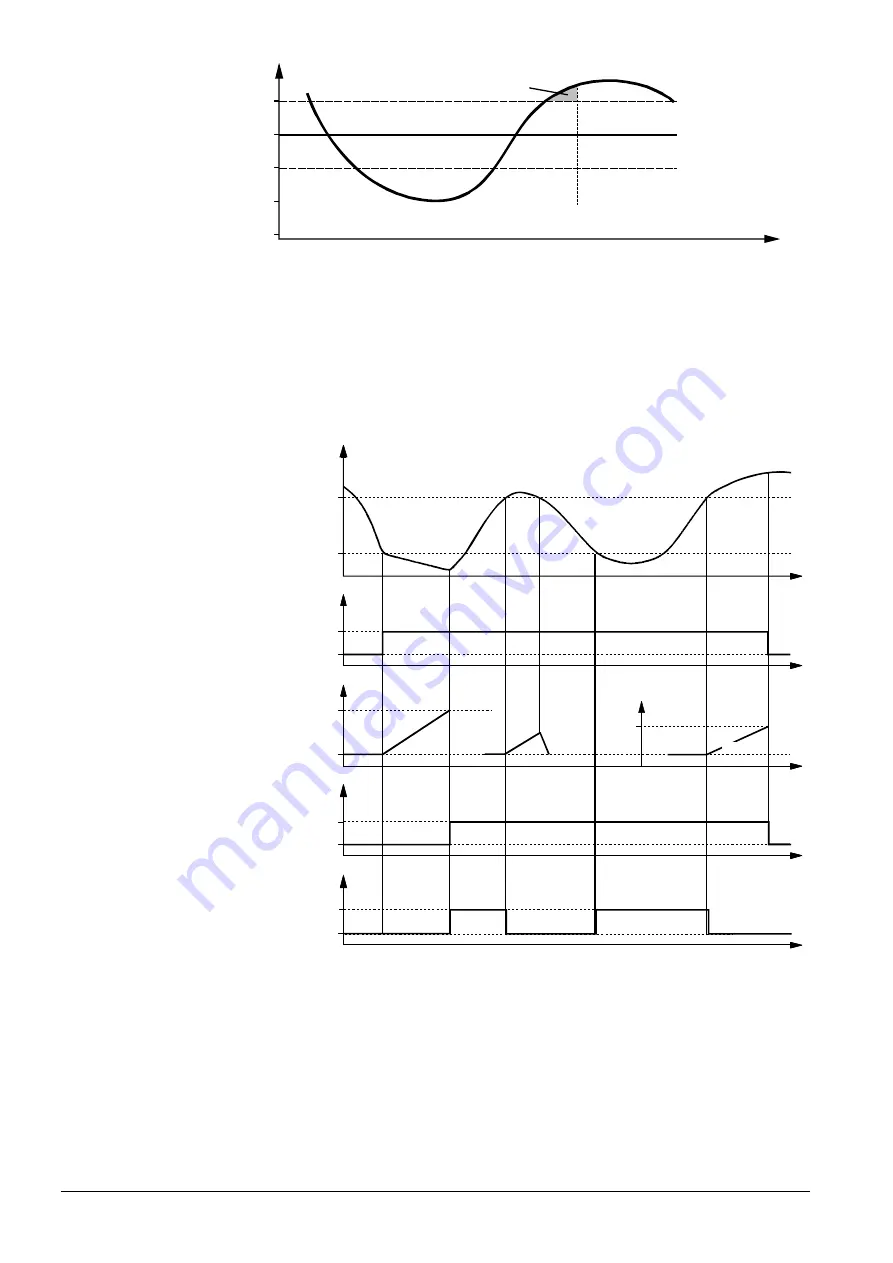

Through the generation of the temperature-time integral it is not only the period of time

that is considered, but also the extent of overshoot. This means that when the over-

shoot is significant, burner stage 2 will be locked earlier.

When the reset integral (area "b" in the diagram) reaches the set value of the reset

integral of stage 2 (point in time t

reset

), stage 2 will be locked and the basic stage switched

off.

1

0

INT

max.

RlsBuSt2

1

0

BuSt2

t

RlsINT

3133

D15

0

1

0

t

t

t

t

BuSt1

max.

TB

1

/

2

SDBo

TBo

RstINT

TBoSetpt -

1

/

2

SDBo

RstINT

BuSt1 Burner

stage

1

SD Switching differential

BuSt2

Burner stage 2

Setpt

Setpoint

INT

Integral

t

Time

RlsBuSt2

Release of burner stage 2

TBo

Boiler temperature

Rst Reset

If, with stages 1 and 2 released, both stages are locked at the same time, the basic

stage will be switched off with a delay of 10 seconds. Switching off in 2 stages also

reduces the pressure shocks in the gas supply line. This prevents unnecessary lockout

in the case of large boiler outputs.

Note